Experience the Ease of Bending with Plate Rolling Machines

Our cutting-edge plate rolling machines utilize less energy and are easy to operate. When bending steel plates, make sure everything is simple and worry-free. Your production infrastructure can benefit from KRRASS's linear guide machines in a number of ways, including decreased capital expenditures, improved edge bending precision, long-lasting and efficient performance, and lower continuing operating and maintenance expenses.

Advantages of Variable Geometry Design

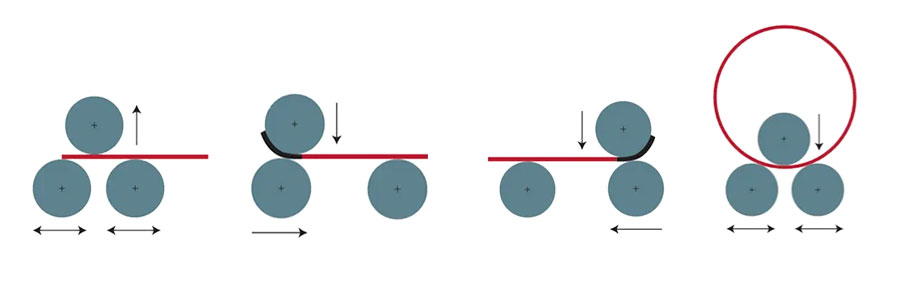

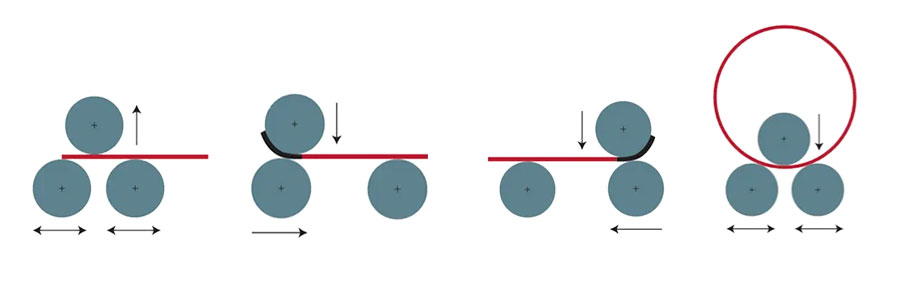

Sheet bending/rolling process

The variable geometry machines from LANGYE are perfect for medium to heavy duty plate rolling machines since they function on par with more costly 3-roller plate rolling machines.

Because the lower rollers have a changeable bending span, the rolling capacity is very large. The rolling power of machines with linear and swing guide systems can be 15–25% more than that of machines with the same top roll diameter.

This design's unique arrangement enables the plate bending rolls to be turned by an integrated planetary gearbox and hydraulic motor and moved independently by hydraulic cylinders (the top roll moves vertically, while the bottom roll moves horizontally). This offers significant benefits by enabling the ideal center distance between the bottom rollers and the bending points.

The roll span can be significantly decreased for thin plates, which improves traction and prevents drive slip and springback.

The bending span of thick plates can be greatly expanded, which lowers plate deformation and bending stresses.

To obtain excellent edge bending, the bottom rolls can also be positioned asymmetrically and manipulated independently of one another.

The ability to feed the plate using a basic unpowered conveyor, which reduces expenses, is another significant benefit of the horizontally moving bottom rollers.

Your industrial infrastructure can profit from variable geometry machines in a number of ways, including a marked increase in rolling capacity, fewer capital costs, and lower continuing operating expenses. For applications requiring large plate thickness (more than 80 mm), they are the most alluring investment.

Advantages of LANGYE Plate Rolling Machine

Large-scale infrastructure

The 16,000 square meter production plant is ideally situated to provide us with quick access to raw materials, transportation, skilled labor, power, and other infrastructure in Nanjing, China's engineering center. Over 40 Years of Excellence

Ongoing product development is the foundation of our superior manufacturing. We have led the industry in design, manufacturing quality, performance, and value for money for more than 40 years. Every one of our designs is created internally, and we provide complete assistance. More than 2500 Machines in Use

In China and abroad, we have produced and put into service more than 2500 equipment. We continue to support the first machine we sold, which is still in use today. More than 400 Recurring Clients

More than 400 of our clients are happy and devoted. They adore our on-demand service and our extensive spare part inventory for every machine we produce, in addition to the exceptional performance of our equipment. You can feel secure in the knowledge that you will receive excellent treatment.

Technical Paraments

| Model | Pressure of Top Roller (T) | Max. Bending Thickness (mm) | Pre-bending Thickness (mm) | Max. Bending Width (mm) | Top Roller Diameter (mm) | Bottom Roller Diameter (mm) | Central Distance (mm) | Main Motor (Kw) |

| For Drive | For Hydraulic | For Movement |

| W11S-4x2500 | 25 | 4 | 3.5 | 2500 | 200 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-6x2500 | 30 | 6 | 5 | 2500 | 210 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-8x2000 | 37 | 8 | 6.5 | 2000 | 210 | 135 | 180 | 4 | 2.2 | 1.1 |

| W11S-8x2500 | 37 | 8 | 6.5 | 2500 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2000 | 37 | 10 | 8 | 2000 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2500 | 55 | 10 | 8 | 2500 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2000 | 65 | 12 | 10 | 2000 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2500 | 75 | 12 | 10 | 2500 | 265 | 145 | 200 | 7.5 | 4 | 1.5 |

| W11S-12x3000 | 75 | 12 | 10 | 3000 | 290 | 150 | 245 | 11 | 4 | 1.5 |

| W11S-16x2000 | 75 | 16 | 13 | 2000 | 265 | 150 | 245 | 7.5 | 4 | 1.5 |

| W11S-16x2500 | 100 | 16 | 13 | 2500 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-16x3000 | 130 | 16 | 13 | 3000 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x2000 | 100 | 20 | 16 | 2000 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-20x2500 | 130 | 20 | 16 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x3000 | 160 | 20 | 16 | 3000 | 380 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| W11S-20x4000 | 230 | 20 | 16 | 4000 | 440 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x2500 | 190 | 25 | 20 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 |

| W11S-25x3000 | 230 | 25 | 20 | 3000 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x4000 | 270 | 25 | 20 | 4000 | 490 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x2500 | 230 | 30 | 25 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-30x3000 | 270 | 30 | 25 | 3000 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x4000 | 380 | 30 | 25 | 4000 | 550 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-35x2500 | 320 | 35 | 28 | 2500 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-35x3000 | 380 | 35 | 28 | 3000 | 510 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-40x2500 | 380 | 40 | 32 | 2500 | 500 | 275 | 460 | 45 | 22 | 5.6 |

| W11S-40x3000 | 430 | 40 | 32 | 3000 | 540 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-40x4000 | 540 | 40 | 32 | 4000 | 630 | 340 | 610 | 55 | 22 | 11 |

| W11S-45x3000 | 540 | 45 | 36 | 3000 | 590 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x2500 | 430 | 50 | 40 | 2500 | 580 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-50x3000 | 540 | 50 | 40 | 3000 | 600 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x4000 | 690 | 50 | 40 | 4000 | 700 | 380 | 700 | 75 | 30 | 15 |

| W11S-55x3000 | 610 | 55 | 45 | 3000 | 620 | 360 | 650 | 75 | 30 | 15 |

| W11S-55x4000 | 850 | 55 | 45 | 4000 | 750 | 420 | 780 | 90 | 37 | 15 |

| W11S-60x3000 | 690 | 60 | 50 | 3000 | 650 | 380 | 700 | 75 | 30 | 15 |

| W11S-60x4000 | 930 | 60 | 50 | 4000 | 780 | 440 | 820 | 90 | 37 | 15 |

| W11S-70x3000 | 850 | 70 | 56 | 3000 | 710 | 420 | 780 | 75 | 37 | 15 |

| W11S-70x4000 | 1150 | 70 | 56 | 4000 | 840 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-75x3000 | 930 | 75 | 60 | 3000 | 740 | 440 | 820 | 90 | 37 | 15 |

| W11S-80x3000 | 1050 | 80 | 65 | 3000 | 770 | 460 | 880 | 90 | 37 | 18.5 |

| W11S-90x3000 | 1150 | 90 | 75 | 3000 | 820 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-100x3000 | 1350 | 100 | 80 | 3000 | 860 | 480 | 920 | 110 | 45 | 22 |

| W11S-110x4000 | 1800 | 110 | 90 | 4000 | 950 | 600 | 1120 | 132 | 55 | 37 |

| W11S-120x3000 | 1800 | 120 | 100 | 3000 | 920 | 580 | 1120 | 132 | 55 | 37 |

| W11S-120x4000 | 2300 | 120 | 100 | 4000 | 990 | 640 | 1280 | 275 | 75 | 37 |

| W11S-150x3000 | 2300 | 150 | 120 | 3000 | 1050 | 660 | 1280 | 2x75 | 75 | 45 |

| W11S-160x3000 | 2500 | 160 | 130 | 3000 | 1080 | 700 | 1360 | 2x75 | 75 | 45 |

| W11S-160x4000 | 2800 | 160 | 130 | 4000 | 1260 | 720 | 1380 | 2x90 | 90 | 45 |

* All dimensions are in millimeters.

* All capacities are 260 MPA.

Depending on your application and feed requirements, we offer both fixed and variable speed machines.

Build Quality and Benefits

1. Durable Steel Structure

The sturdy steel construction of LANGYE's plate bending equipment is derived from heavy-duty sheet metal. A sturdy box-shaped chassis with interlocking and reinforcing ribs connects these frames. To enable parallelism of all axes and precision surfaces, as well as lifespan and essential precision qualities for the machine, roller guides are manufactured with a single fixed reference point.

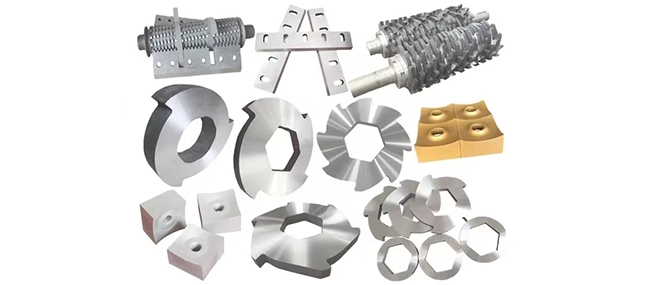

2. Roller for Plate Bending Machine

The most crucial part of our sheet metal bending equipment is the roller. LANGYE employs high-precision CNC lathes to machine forged carbon steel rollers with the right diameter. Our rollers are efficiently connected to the planetary gear system by means of a special spline design. Compared to welded connections provided by other manufacturers, this design lowers the number of roller failure spots.

Plate Rolling Machine Crown

In order to compensate for roll deflection during bending, our rolls are crowned. It is possible to purchase custom crowned rolls in a variety of materials and thicknesses.

Hydraulic Gear System for Sheet Metal Bending Machines

When the coiled workpiece is less than the maximum thickness, our 4-roll sheet metal bending machines may function at less than full capacity thanks to a hydraulic mechanism, which guarantees further energy savings.

Our machines use the incredibly efficient LANGYE Planetary Drive SystemTM, which reduces speed by increasing the number of gear and pinion stages while removing the energy loss that comes with hefty transmission systems.

Operational Benefits

Pre-bending, or pre-clamping

Depending on the operator's preference and level of skill, edge bending can be done either before or after shell rolling. It is possible to roll and edge bend thin plates simultaneously.

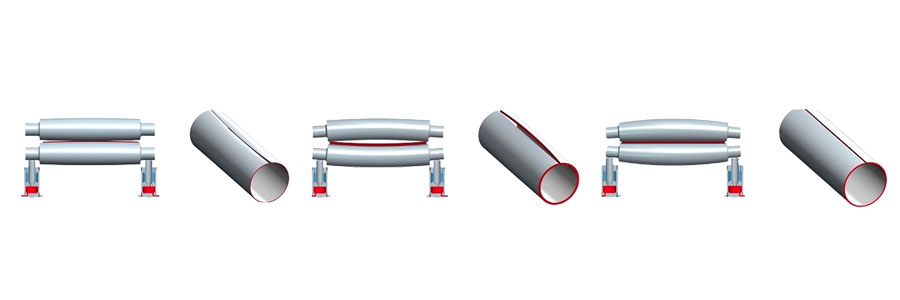

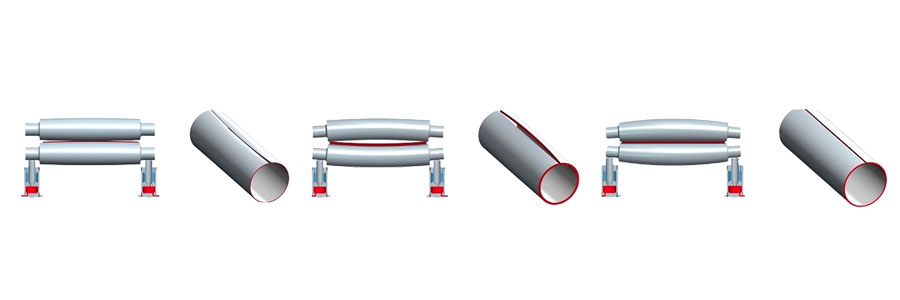

Easy Cone Bending

With the W12 series, cone bending is an easy process. To obtain the cone bending geometry, the bottom roller must be inclined. On certain models, an electronic microprocessor is in charge of controlling and monitoring this.

Additionally, our control system makes sure that after bending, the cone returns to a parallel configuration with ease and accuracy, enabling accuracy in repeatable tasks.

Additional Features of Sheet Metal Bending Machines

The following extra features and accessories are available at customer request in addition to our superior design and production excellence.

1. Rollers that are case-hardened

Additional resilience and endurance are offered by induction-hardened rolls, which have a surface hardness ranging from 42 to 55 HRC.

2. Full Fabrication Package for Windmill Towers

consists of hardened rolls, an inclined conveyor, center and side shell supports, and PLC/CNC capabilities.

3. Supports for the Center and Side Shells

Center and Side Shell Supports improve worker safety while streamlining operations, lowering operating expenses, and boosting productivity.

4. Hard Rollers Plated in Chrome

The dairy and pharmaceutical industries employ hard chrome-plated rollers for specific purposes.

5. Tables with tilts

The sheets that are fed in at a particular angle are supported by tilt tables. Useful for longer sheets in particular.

6. Belt Conveyors

The machine's performance and lifespan are increased when the sheets are longer because the powered conveyor belts make feeding the sheets simple.

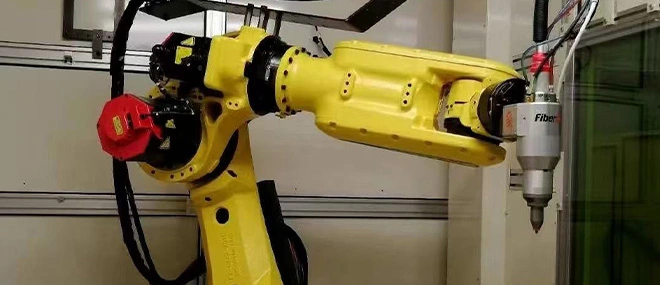

7. Controls for PLCs

PLC controllers offer accuracy and convenience of use while recognizing when preventive maintenance is necessary to prolong machine life and maximize output.

English

English