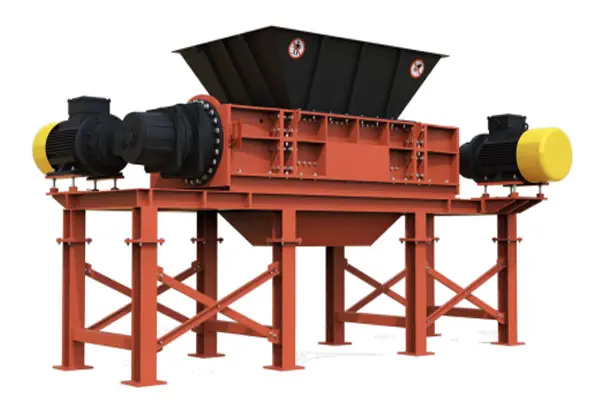

Details of Two Shaft Shredder

The Twin Shaft Shredder is made with high torque cutting technology that is adaptable to a range of recycling needs. It can shred large pieces of hard materials like tires, car shells, metal drums, scrap steel and aluminum, household trash, hazardous waste, and industrial waste, among other things. This design maximizes the benefit and regulates the output material's size based on the various customer requirements and the material that needs to be shredded. The German DIN5480 standard is used by the gearbox that is attached to the rotor. Large torque transmission, a dependable connection, low speed, low noise, and minimal maintenance costs are further benefits of the shredder. The Siemens PLC program controls the electrical component, which has the ability to automatically detect overload protection. Schneider, Siemens, ABB, and other well-known brands are used in the primary electrical components.

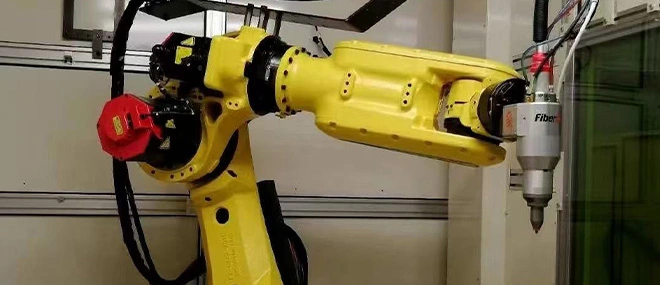

For the plastic recycling sector, LANGYE offers the most comprehensive and excellent shredding and recycling options. To obtain the best material crushing effect, design the optimal shear angle, the most appropriate shear speed, and the most sensible feeding technique based on the material's characteristics. Then, rely on strong CNC machining centers to ensure the precision of the equipment.

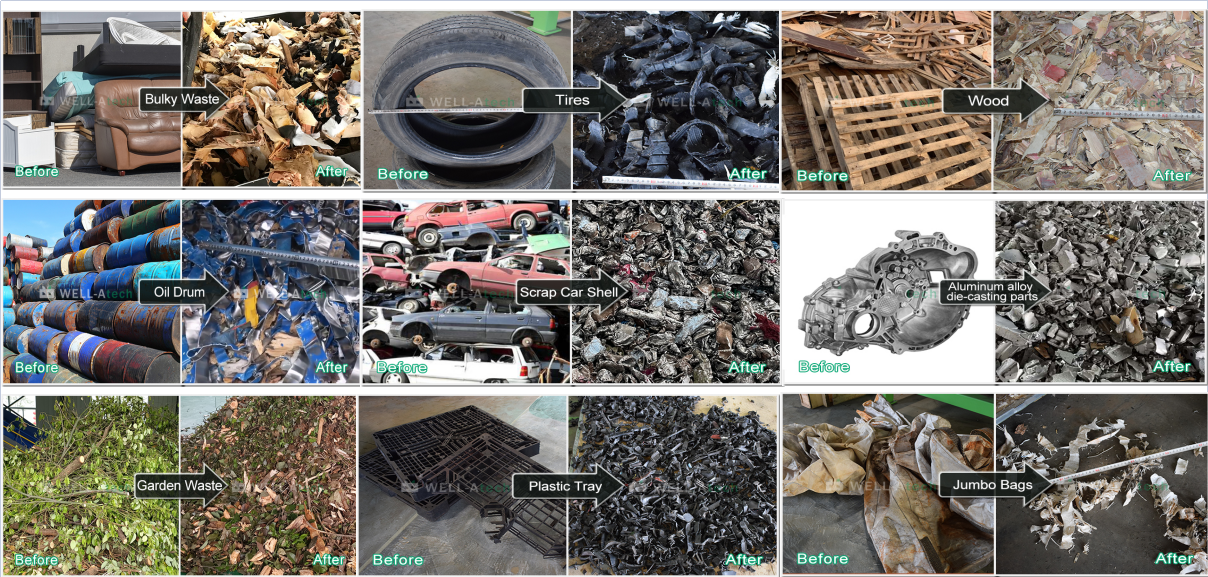

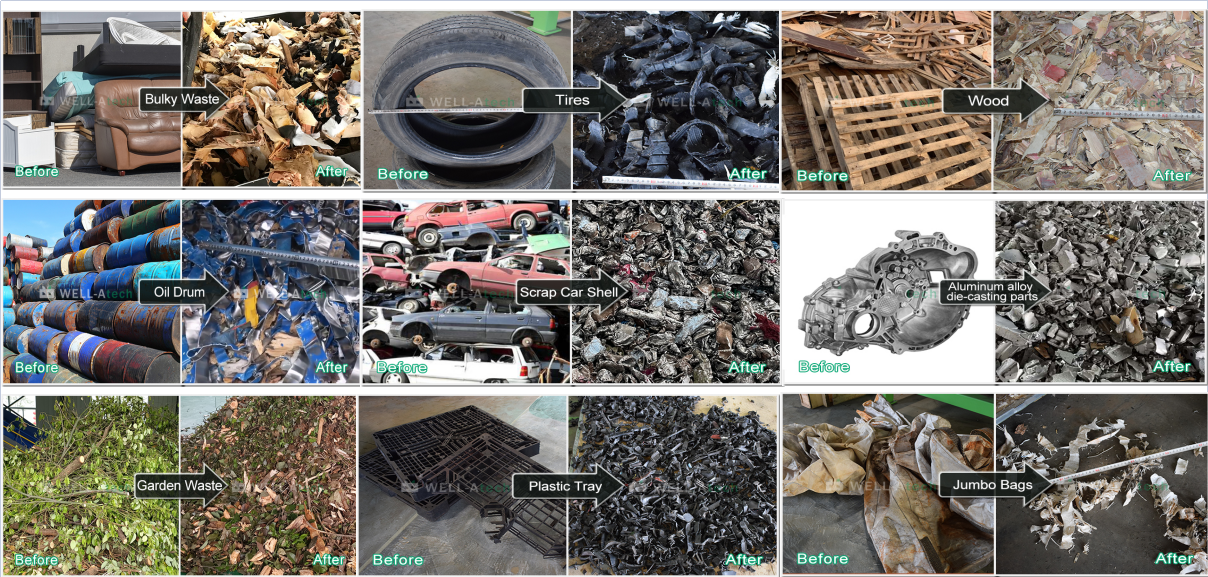

Application of Two Shaft Shredder

Bulky garbage includes things like wooden cabinets, sofas, mattresses, tables, chairs, and bed frames.

Tire waste from the home: used tires

Old clothing, leather, textile trash, and other general industrial waste are examples of industrial waste.

Rice straw, wood, bagasse, corn stalks, coconut shells, and so forth are examples of biomass straw.

Hazardous solid garbage includes things like oil drums, container bags, radioactive material, and medical waste.

Used automobile shells, die castings made of aluminum alloy, home appliances, etc. are examples of metal waste.

Output Display

Features

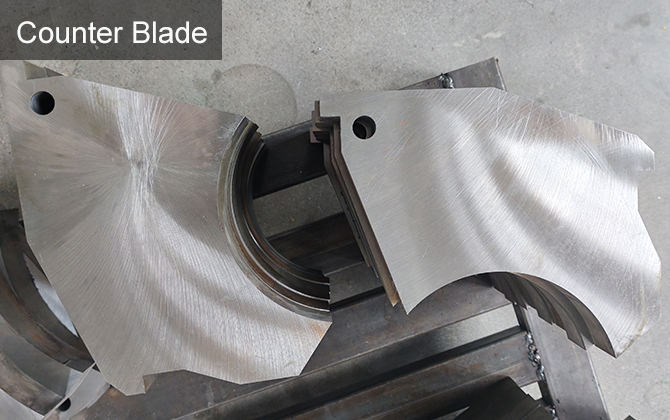

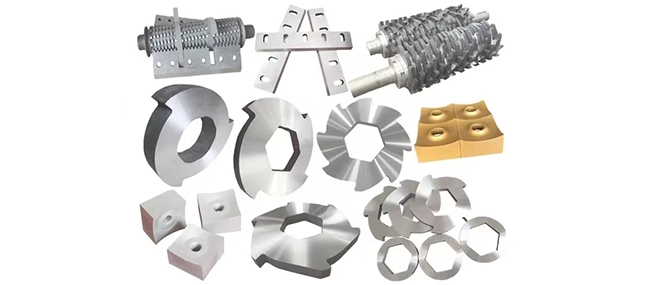

DILLIGUR/HARDOX imported NiCrMo high alloy steel as a raw material

Blade thickness and tooth count can be changed.

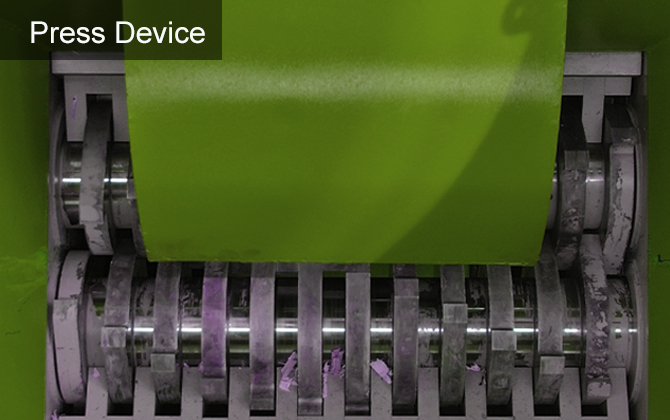

A consistent pulverizing force is produced by the blade's "V" shaped configuration. Blade structure and material: premium alloy steel CrMoV. Depending on the needs of your application, a variety of materials and configurations are also available. High wear resistance and exceptional longevity are guaranteed by the double sidewalls' construction from HARDOXTM wear-resistant steel plate.

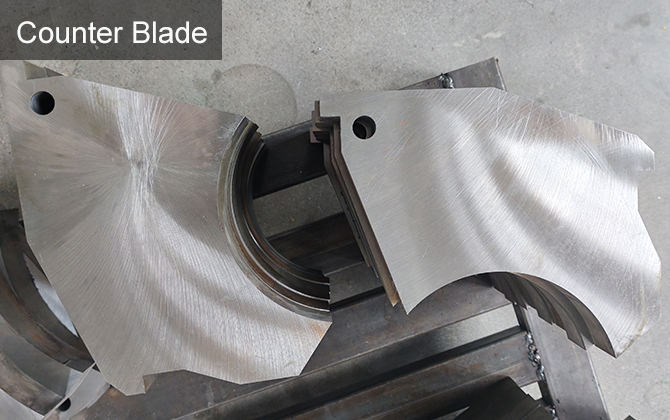

To avoid material entanglement, the crushing chamber has reverse blades on both sides.

Design that may be removed individually for simple upkeep.

Parameters

| Model | Crushing Chamber(mm) | Rotation Diameter (mm) | Power(kw) | Weight(kg) | Size(L*W*H mm) |

| WEDS-1000 | 1000*700 | φ330 | 30+30 | 4500 | 3150*2150*2500 |

| WEDS-1200 | 1200*800 | φ400 | 45+45 | 8000 | 4100*2300*2800 |

| WEDS-1600 | 1600*1100 | φ550 | 90+90 | 16000 | 5630*3160*3200 |

| WEDS-1800 | 1800*1000 | φ500 | 75+75 | 22000 | 6110*4957*5520 |

| WEDS-2000 | 2100*1300 | φ650 | 200+200 | 29000 | 6700*3700*3600 |

Customer Cases

English

English