Metals, Woods, Plastics, Composites and so on.

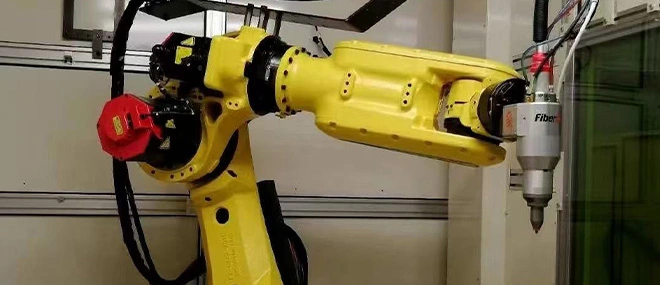

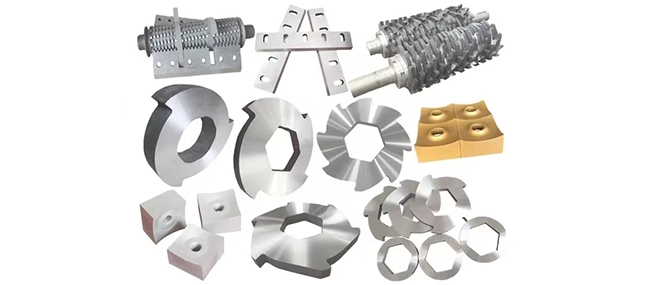

Table CNC cutting machines are highly versatile and capable of cutting a wide range of materials, making them suitable for various industrial and fabrication applications. These machines can efficiently cut metals such as steel, aluminum, and copper, which are commonly used in manufacturing and construction. Additionally, they can handle different types of wood, from softwoods like pine to hardwoods like oak, making them ideal for woodworking projects. Plastics, including acrylic, PVC, and polycarbonate, can also be precisely cut, which is useful for creating custom parts and prototypes. Furthermore, table CNC cutting machines can cut composites, which are materials made from two or more constituent materials with different physical or chemical properties. This includes materials like fiberglass and carbon fiber, often used in aerospace and automotive industries. Lastly, some CNC machines are equipped to cut softer materials like foam and rubber, which are used in packaging, insulation, and gasket manufacturing. The specific cutting capabilities depend on the type of cutting tool used, such as plasma torches, laser heads, water jets, or mechanical routers, each suited for different materials and thicknesses. This versatility makes table CNC cutting machines an invaluable tool in a wide array of industries.

English

English