Standard Equipment

Source of Hypertherm Power

THC Sensor-Based Automatic Torch Height Control

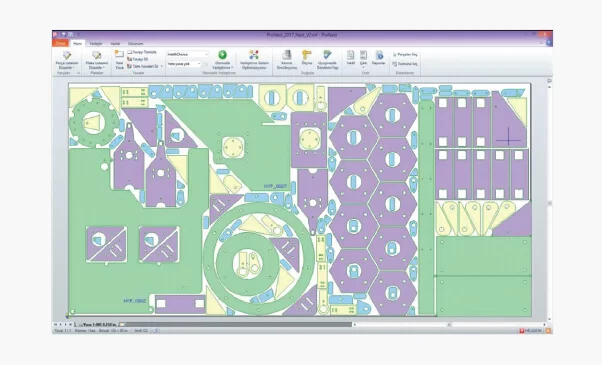

Software for CAD/CAM

Unit for Hypertherm Auto Gas Control

Both sides of the bridge are powered by servo motors. The X-Axis

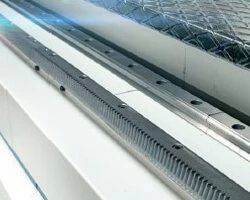

Accurate linear dual guiding, helical rack, and pinion

Vacuum table and filtering unit outputs and inputs with CNC control

Accuracy of placement +/- 0.1 mm

40 m/min is the positioning speed.

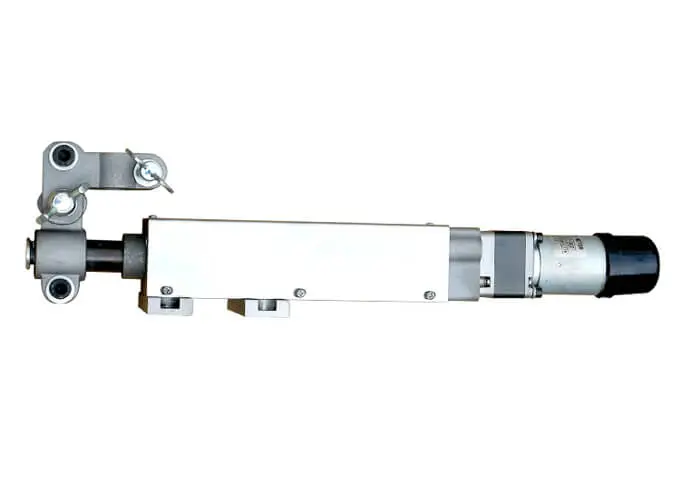

Collision sensor for a torch

Separate design for cutting table and bridge

Optional Features

CNC Unit with Hypertherm Edge Connect/TC

Alternatives to the Hypertherm power source

Options for an Auto Gas Console

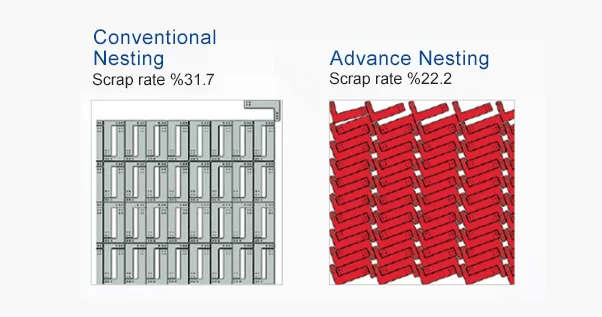

CAD/CAM software from Lantek, automated nesting

Pronest CAD/CAM software from Hypertherm

The Filter Unit

Starter package for consumables

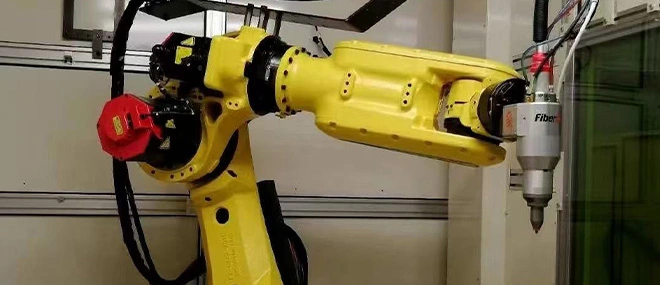

5-Axis cutting head

Two bridges

Cutting pipes

Tanaka Oxy Torch, Messer Oxy Torch, and Oxy cutting head

Multiple plasma heads

Real Hole

Technicial Specifications Of Carbon Steel Cutting Machine

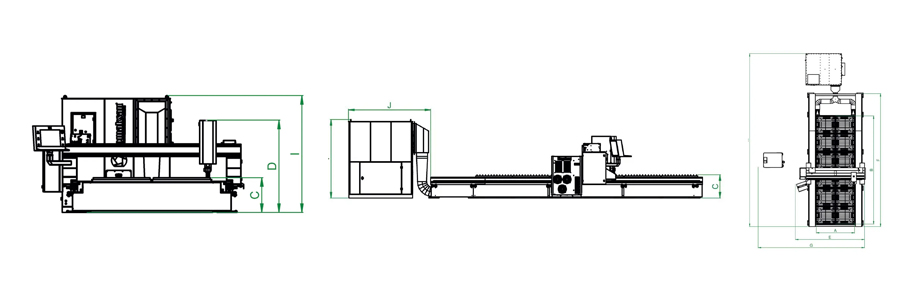

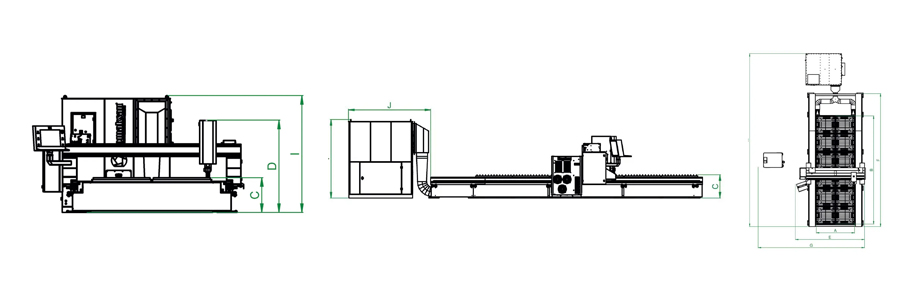

Technical Parameters Of Plasma Cutting Machine

| P-Series Plasma Cutting | Cutting Width | Cutting Length | Table Height | Height | Width | Length | Width (Including Power Unit) | Length (Including Filter) | Filter Height | Filter Length |

| A | B | C | D | E | F | G | H

| I | J |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| A1500 | 3000 | 1500 | 3100 | 650 | 2000 | 2320 | 4500 | 5500 | 6500 | 2200 | 2000 |

| 4000 | 1500 | 4100 | 650 | 2000 | 2320 | 5500 | 6000 | 7500 | 2200 | 2000 |

| 6000 | 1500 | 6100 | 650 | 2000 | 2320 | 7500 | 6000 | 10000 | 2200 | 2500 |

| A2000 | 6000 | 2000 | 6100 | 650 | 2000 | 2820 | 7500 | 6500 | 10000 | 2200 | 2500

|

Introduction to Configuration

1. HYPERTHERM CUTTING HEAD

Excellent cutting quality, long lifespan, high cutting speed, low operating costs, and high productivity. provides a broad range of cutting from extremely thin to extremely thick sheets.

2. CNC CONTROL UNIT ESA / HYPERTHERM

Plasma processes can be effectively and simply managed because of their simple functioning.

3. HYPERTHERM POWER SOURCE

High dependability and simple consumable replacement are made possible by efficiency, quick cutting, and a quick processing cycle. Benefits include optimum productivity, low operating costs, and excellent cutting quality.

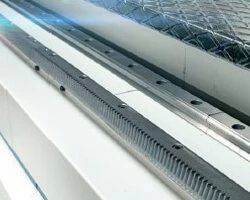

4. RACK PINION AND LINEAR GUIDING

This plasma cutting machine's dual guiding system—rack pinions and linear guides—achieves high accuracy cutting.

5. CABLE TRAY CARRIERS

cable channels that meet CE requirements, silent operation, robustness, Its non-breaking and anti-friction qualities extend its useful life.

6. PARTIAL PNEUMATIC SUCTION SYSTEM

Only the cutting area's pneumatically operated hatches are opened using the PLC software. In this manner, it is possible to achieve a stronger suction while using less energy.

Hypertherm's latest Computer Numerical Control (CNC) platform, EDGE® Connect, offers unparalleled dependability, robust embedded capabilities, and a high degree of customization. The system, which is built on our exclusive, market-leading Pho-enix® CNC platform, offers improved hardware and new, cutting-edge software features, such as ProNest® CNC automatic nesting that delivers SureCutTM technology. EDGE Connect CNCs can be configured in the field using software tailored to the plasma cutting machine application, making setup, modifications, and upgrades simple. In addition to supporting plasma, oxyfuel, and waterjet applications, the user-friendly device has an intuitive graphical user interface and improved cutting performance.

Even novice operators can cut production parts in less than five minutes with the patented CutPro® Wizard.

The cutting station and manual motion can be easily set up and operated with the help of the on-screen Software Operator's Console (Soft OpCon).

Using installed factory or custom cut charts, automated and expert control is provided through integrated communications with plasma and torch height control systems.

Custom cut charts can be made available to the CutPro Wizard or produced and managed within the part application.

The Windows® 10 Enterprise operating system powers EDGE Connect.

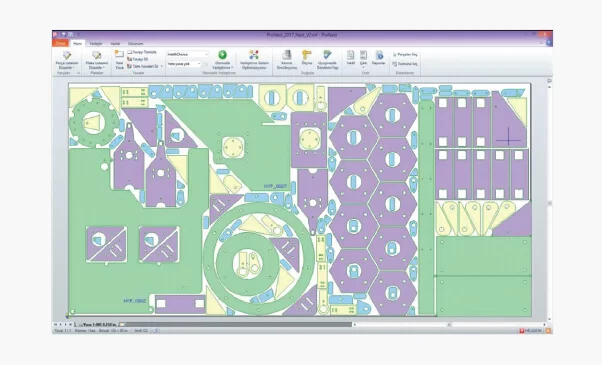

CAD / CAM Softwares for Plasma Cutting Machine

A robust CAD/CAM component nesting program, ProNest® LT (previously TurboNest®) was created for light industrial, mechanized cutting in production settings. It offers a single software program for all of your oxyfuel and standard plasma cutting equipment.

Design and development of a portion

Integrated 2D CAD software for CAD file creation and editing

To create common parts from templates, use the Variable Shape Parts library.

Importing and converting CAD/CAM

Import CAD files (file formats that are industry standard)

Bring in a PDF

Static images are converted to CAD using raster to vector.

Error detection and automatic CAD file rectification

Automatic reduction and smoothing of ellipses and spline

Divide several components from a single CAD file.

CAD layers are automatically mapped to processes (cut, mark, etc.)

Quick and simple job setup

SureCutTM technology and integrated enterprise process

Interactive manual nesting

Comprehensive reporting

Costing made simpler

Selection of output

A post-processor that produces NC

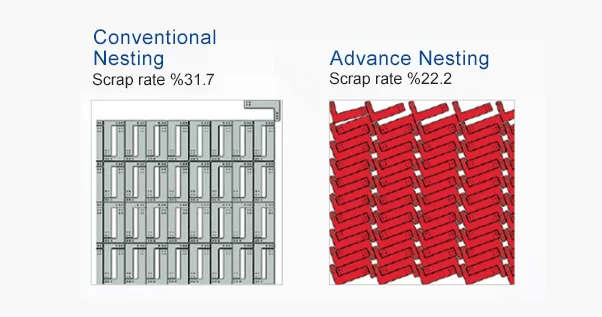

provides optimal nesting efficiency for both human and automated component nesting.

Alignment, copying, moving, reversing, and semi-automatic geometrical operations

A sophisticated nesting algorithm maximizes a material's use while reducing scrap.

able to work with scraps from earlier procedures or standard sheets that are kept in the warehouse.

Automatic determination of the cutting path

Cost/time analyses

Prior to actual cutting, a simulation

CAD system, DXF, DWG, IGES, Step, and other file formats can be imported and exported using Smart Parts.

Part drawing module, call parts, machining, CNC code generation, automatic or manual nesting, searching for sheet metal stocks, etc.

Film burning, specialized piercing, quick laser, micro-joints, head direction management, edge binding, and a variety of input/output techniques

Complex features and software

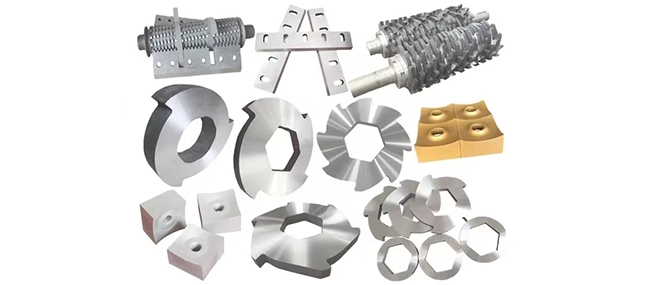

Head Options of Plasma Cutting Machine

1. Beveling Head (5-Axis)

The 5-axis beveling head from KRRASS is made for angle and 3D cutting. All angles up to 45° are generated automatically, allowing the user to enter the required angles as needed. Because of the height sensing sensor, straight vertical cuts can also be made with less maintenance.

provides bolt hole quality

Automatic angle correction

Time-saving: minimal setup time

Superb contouring and cutting

Low costs of production

2. Oxy Cutting

Oxygen cutting is another feature of KRRASS CNC Controlled plasma cutting equipment. Our oxygen head-equipped machines can cut up to 200 mm, and with specific design choices, this limit can be raised.

3. Plasma Cutting

For higher quality, more power, more accuracy, and more reliable cutting, the plasma cutting machine makes use of Hypertherm's unique technology.

reduces the cost per cut.

Power Pierce: Enables powerful production piercing by repelling molten metal during piercing.

Long Life: Control is used to modify the gas intake and flow rate.

High Definition: Consistent, high-quality cutting that aligns and emphasizes the arc

High Definition: Provides faster cuts and higher arc densities while preserving arc stability and better cut edges.

increases the hourly rate of cutting

Dust Collector Filter System

A filter is required for the extraction of smoke, dust, and pollutants during plasma cutting machine operations. improves everyone's working conditions, especially for plasma operators. Because of its precisely defined dimensions, it is shipped in a single piece, meaning that all accessories are pre-set and ready to use. A crashing plate holds particles that are carried by the filthy air that enters through the filter cabin's side walls. The air speed is reduced in this segment to achieve the required filtration rates. Additionally, large, corrosive particles and sparks that might come into contact with the filter are sent to the collecting bucket beneath the bunker. As a result, the filters' lifespan is extended. BIA-approved filter materials are chosen based on application and tested in accordance with DIN EN 60335-2-69 appendix AA to capture other dusts and smokes that make up the contaminated air. The jet pulse cleaning mechanism automatically cleans the dust that is stored. Through the use of a fan, cleaned air is drawn from the cabin and discharged into the ideal atmosphere.

English

English