Details of Single Shaft Shredder for Sale

A common single shaft shredder for materials with trace amounts of metal, like plastics, paper, wood, and discarded wire and cable, is the SR Series Single Shaft Shredder. The material's characteristics and the needs for further processing dictate the screen size. The ground-up granules can be treated further or utilized again. A high level of machine safety is provided by intelligent electrical controls.

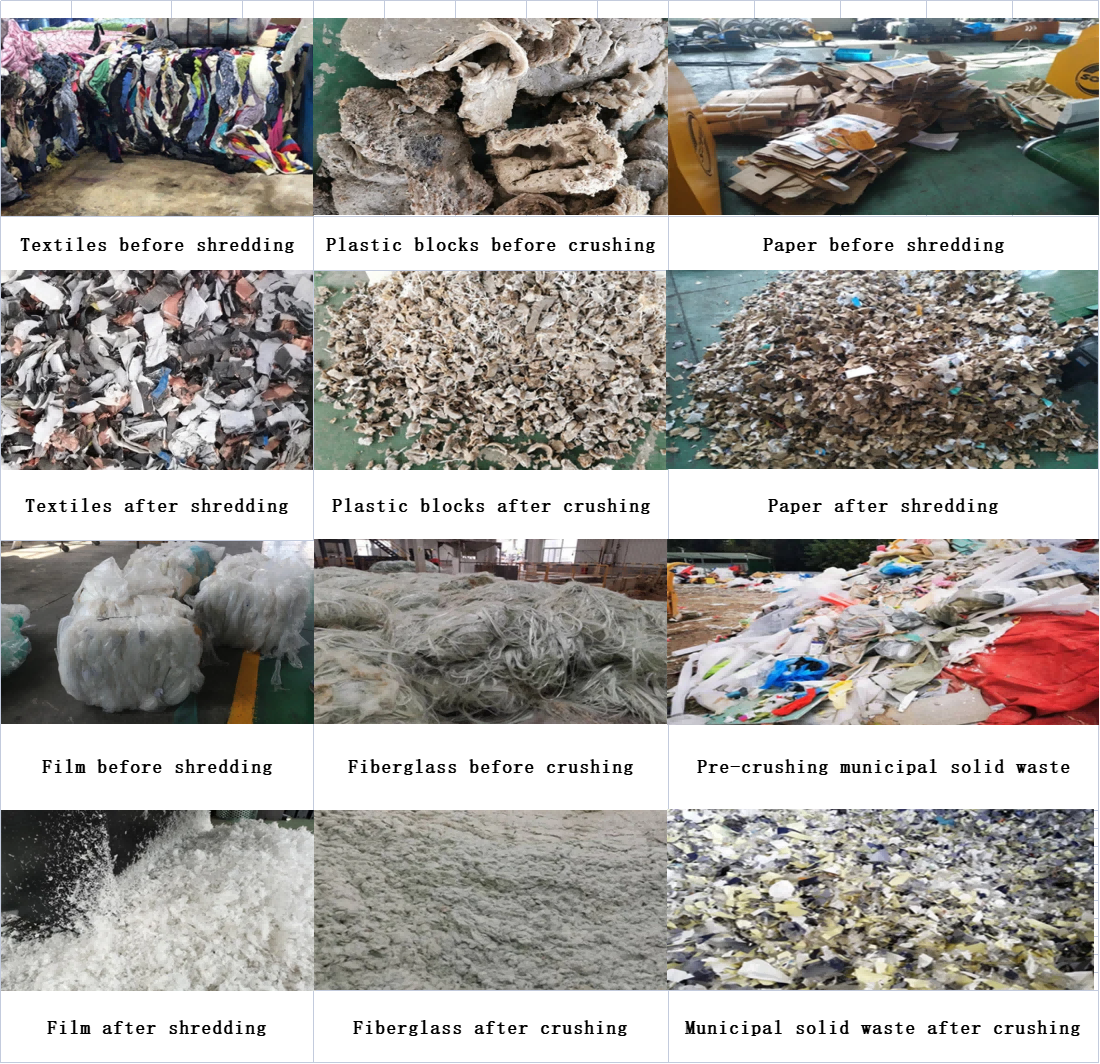

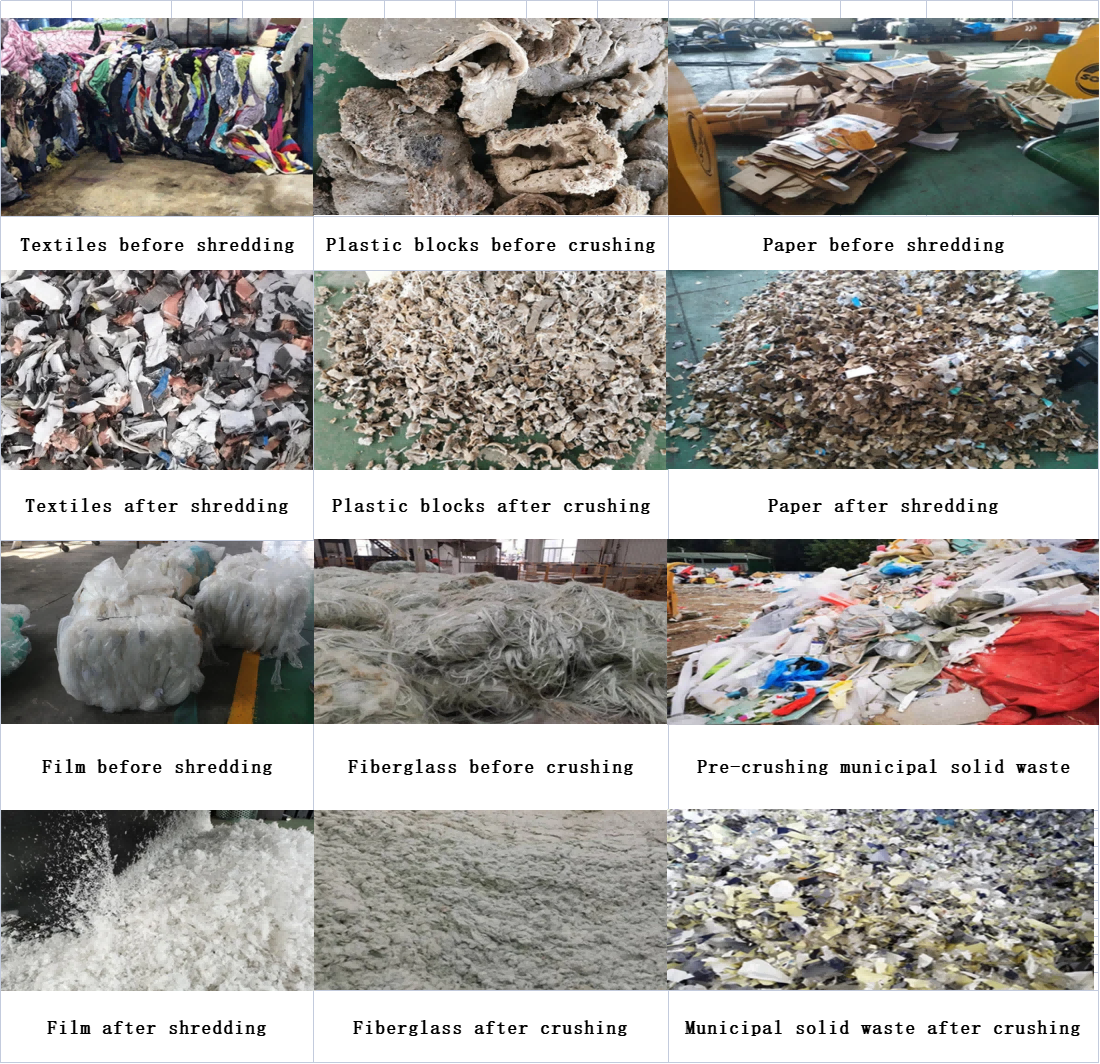

Uses: ABS, PC, PET, plastics, and plastic blocks

PE, PP, plastic film.

Incinerators for waste

Copper, steel, iron, aluminum, and metals

Cables and wires

Wood

Fiber of Glass

Electronic Trash

Medical waste and solid waste

Features of Single Shaft Shredder

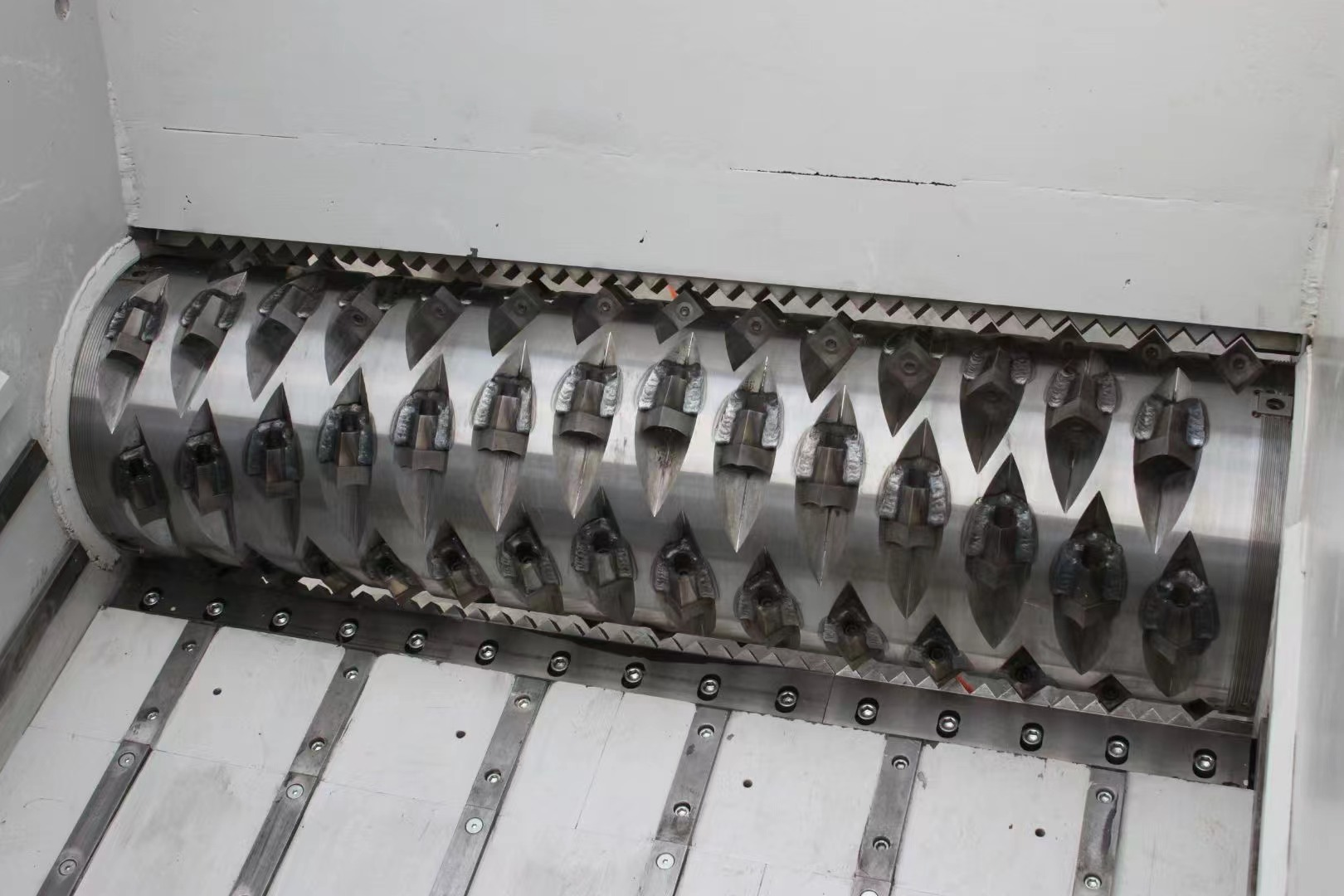

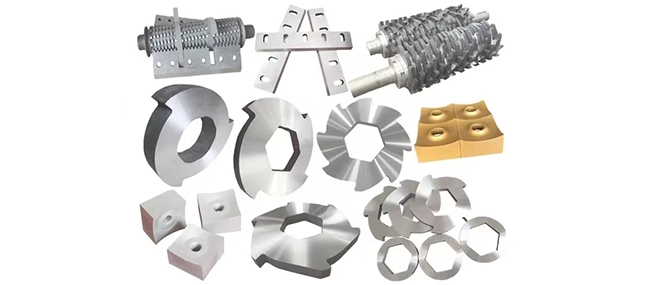

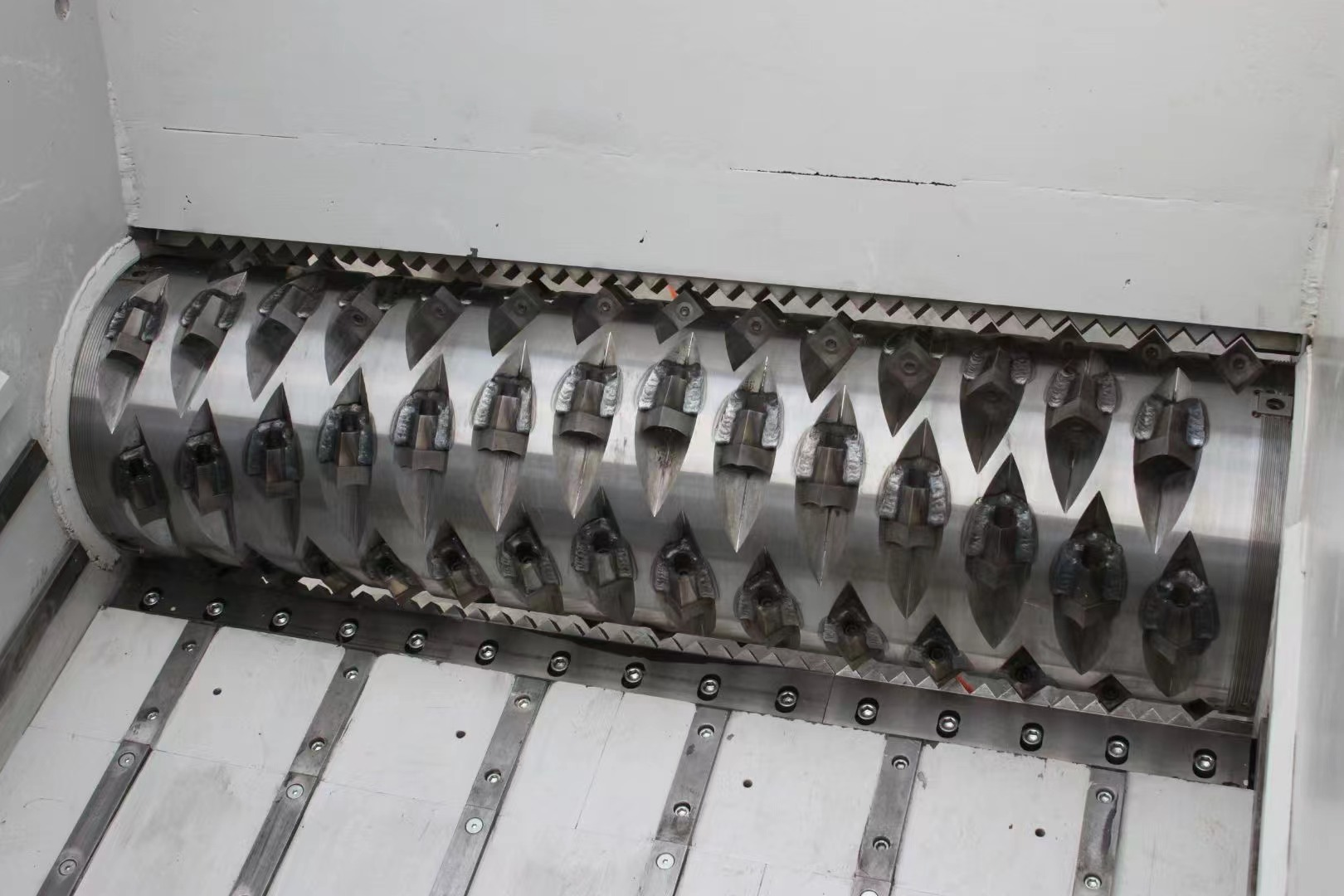

"V" shaped rotor: To avoid material accumulation, this rotor is outfitted with double-edged knives. The rotary blades come in a variety of shapes and compositions and are composed of wear-resistant CrMoV high alloy steel. The cutting blades can be used repeatedly without needing to be replaced and have a long service life.

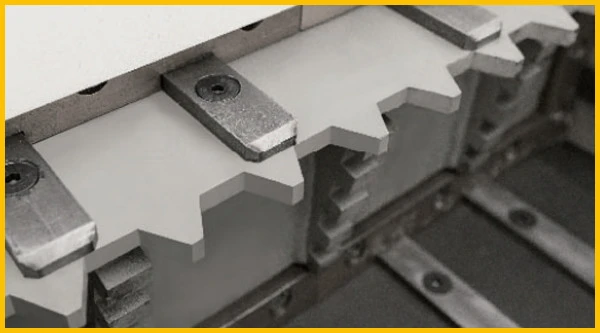

Adjustable Fixed Blade: The fixed blade is composed of a surface-coated wear-resistant material that enables the pulverizer to handle tougher or more abrasive materials and provide long-term stable operation. The fixed blade spacing may be adjusted for a wider range of pulverizing.

Screen Unit: Depending on the customer's production needs, the screen unit can be swapped out for a range of mesh sizes and configurations. To protect the operator, the single shaft shredder will immediately stop when the screen unit is opened. For ease of maintenance, the screens are made and put in pieces.

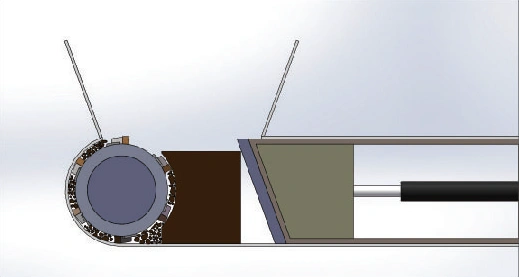

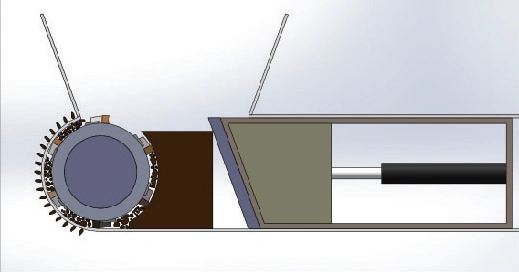

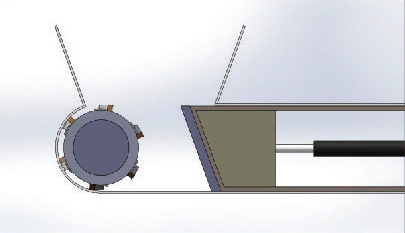

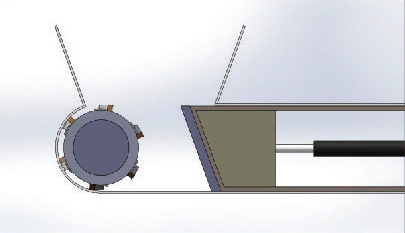

Transmission System: Intelligent hydraulic control is used; the cylinder runs at its quickest speed when crushing easily shreddable materials, and the pushing speed is reduced when crushing harder-to-shred materials to avoid overloading the rotor. Every hydraulic system has a cooling system to improve stability and longevity over extended use.

The operation involves the following steps: the propulsion device is driven by the hydraulic system, the motor transfers power to the rotor via the belt and gearbox, the rotor's upper and lower stator blades perform the cutting movement, materials are fed from the feeding hopper and forced through the propulsion chamber between the rotor blades, the upper and lower stator blades tear up the materials, and the materials are then reduced to particles.

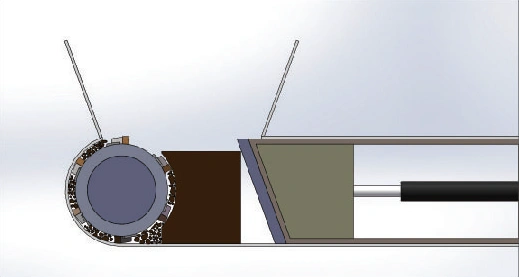

Step 1: State of preparation.

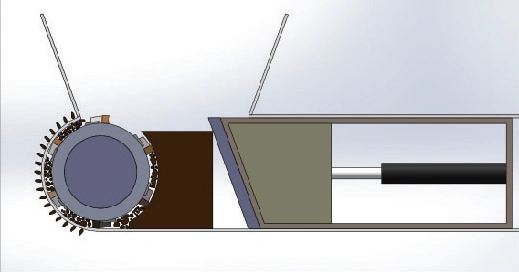

Step 2: The material is forced into the rotor by the hydraulic system.

Step 3: Particles of the material are broken up and then dropped through a screen.

Range of applications:

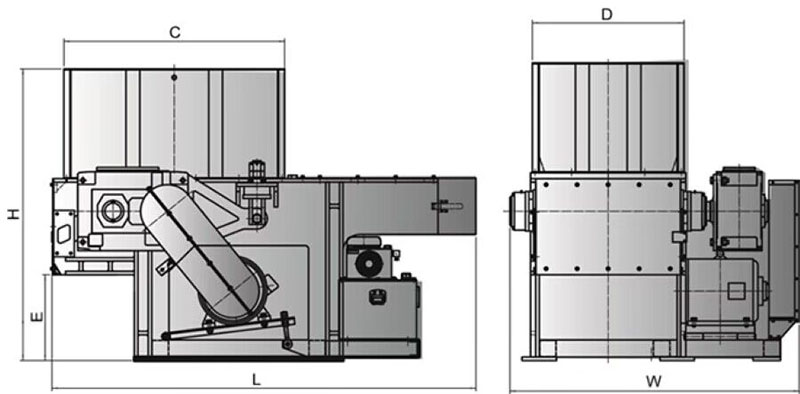

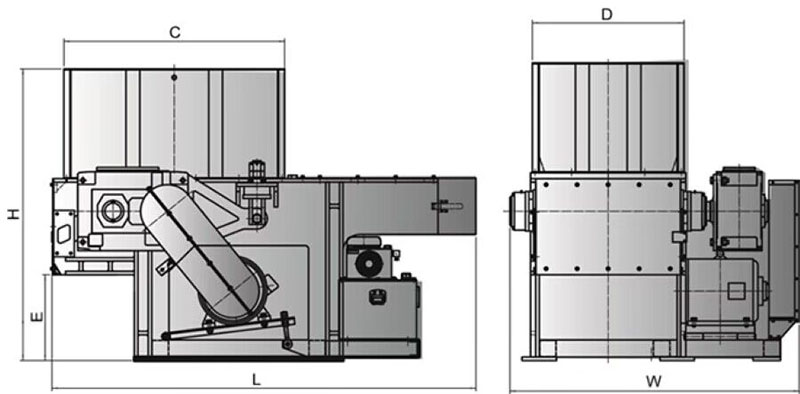

Paraments:

| Model | SR600 | SR750 | SR900 | SR1400 | SR1600 | SR2100 |

| Main shaft speed(rpm) | 73 | 73 | 73 | 73 | 73 | 73 |

| Ram travel(mm) | 500 | 820 | 820 | 820 | 1000 | 1000 |

| Rotor diameter(mm) | 220 | 400 | 400 | 400 | 480 | 480 |

| Number of rotor blades(pcs) | 23 | 44 | 52 | 80 | 94 | 122 |

| Number of fixed blades(pcs) | 4 | 6 | 6 | 10 | 12 | 16 |

| Discharge height(mm) | 500 | 610 | 610 | 610 | 950 | 950 |

| Screen holes diameter(mm) | 40 | 40 | 40 | 40 | 40 | 40 |

| Motor power(kw) | 18.5 | 37 | 45 | 75~90 | 2x55~2x75 | 2x75~2x90 |

| Hydraulic power(kw) | 1.5 | 2.2 | 2.2 | 5.5 | 7.5 | 7.5 |

| Cutting chamber dimensions(mm) | 540x600 | 830x708 | 830x840 | 830x1302 | 1000x1533 | 1000x1995 |

| Overall dimensions(LxWxH)(mm) | 1800x1350x1700 | 2810x2000x2115 | 2810x2100x2115 | 2810x2890x2115 | 3475x4100x2700 | 3475x4900x2700 |

| Weight(kg) | Approx 1600 | Approx 4460 | Approx 4560 | Approx 6200 | Approx 10800 | Approx 13000 |

Customer Cases

English

English