Structure

A fully welded box bed frame that is incorporated with the workstation is part of the design of the shearing machine.

High rigidity can be supplied by the frame to offset the torque load brought on by the shear force.

Because of the machine's vertical linear movement with respect to the bottom blade, the sheared sheet is guaranteed to undergo little distortion and to remain precisely straight.

Control System

The controller for the machine is a Delem brand DAC360 CNC system, which has been updated to the DAC360T touch screen version. The Netherlands is home to the Delem brand.

The rear stop, blade angle, and blade gap may all be controlled and adjusted with the system.

As an alternative, there are the E21S digital display controllers.

The Back of HydraulicShearing Machine

Main Motor

High-Capacity Main Motor Options: Depending on your needs and preferences, our high-capacity main motor can be tailored to fit well-known Chinese brands like Wannan or internationally recognized names like Siemens.

Voltage Customization for Particular demands: We provide voltage customization with options such as 3-phase / 220 V / 60 Hz, 3-phase / 380 V / 60 Hz, 3-phase / 415 V / 60 Hz, and other combinations catered to your particular demands in order to suit unique operational needs.

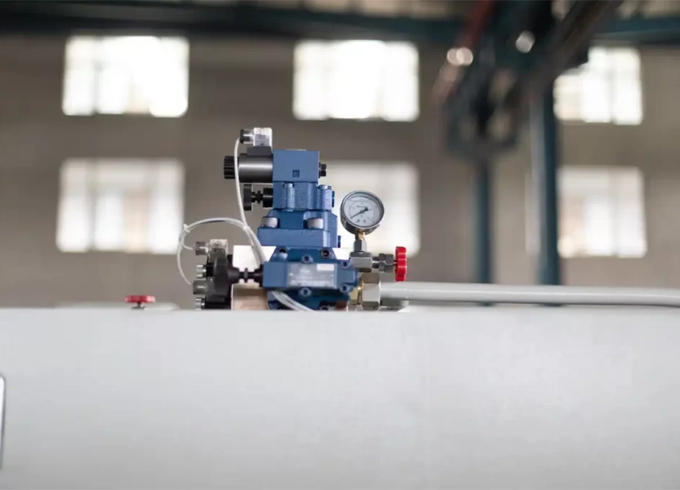

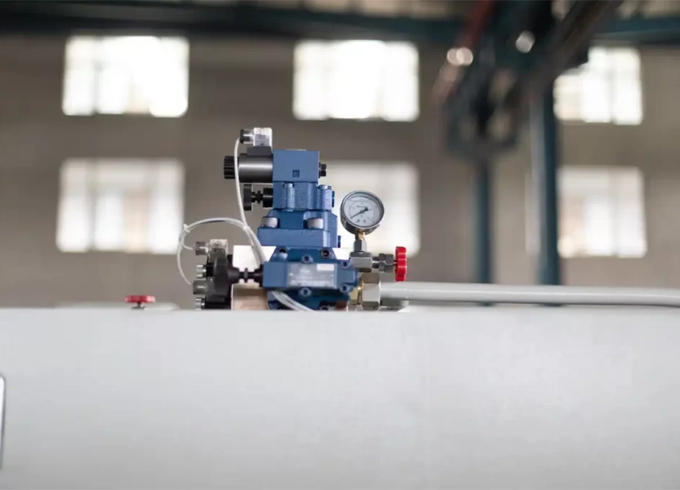

Rexroth hydraulic system

1. Making Use of the Well-Known Rexroth Hydraulic Valve Block:

By using a widely known and dependable part, the Rexroth hydraulic valve block guarantees the best hydraulic performance.

2. Preventing Oil Leakage and Valve Jamming:

The machine's oil pressure overload prevention technology reduces the likelihood of valve jamming and oil leaks. This increases the equipment's durability and dependability.

3. Oil Pressure Monitoring in Real Time for Continuous Operations:

Real-time oil pressure monitoring is provided to guarantee continuous oil circuit operations and reliable equipment performance. This function increases the machine's efficiency by enabling proactive maintenance and changes.

Efficient Workbench

1. Less Friction for a Smooth Plate Surface: By reducing friction between the plate and the table, the ball-type front support guarantees a smooth plate surface.

2. Improved Cutting Efficiency through Easy and Quick Feeding: Our machine's revised feeding system makes it easier and faster to feed materials, which greatly increases cutting efficiency.

3. Safety and Feeding Height Customization: With a thoughtfully crafted feed port, our equipment complies with international safety regulations. It provides a maximum feeding height of 20–25 mm plus the sheet thickness, and a minimum feeding height of the thickness of the sheet. A front fence and side guardrail guarantee operator safety while in operation, and adjustable height screws make it simple to customize the feeding height.

Ball Screw & Liner Guide Backgauge

Improved Accuracy:

By guaranteeing precise placement and reducing errors, linear guide rails help increase machine movement precision.

Consistent and Fluid Motion:

The backgauge can travel smoothly and consistently thanks to the linear guide rail, which also ensures uniform shearing and lowers the possibility of anomalies.

Decreased Wear and Friction:

By reducing friction, advanced linear guide technology prolongs the life of equipment and preserves backgauge accuracy over time.

Lubrication Device

Improved Convenience and Speed: By providing improved convenience and speed, our product guarantees effective and fruitful operations.

Two Operational Flexibility Models: Our device offers users versatility by accommodating a range of operational preferences and coming in both automatic and manual modes.

Easy Model Selection: By selecting between automatic and manual models, users may easily customize the machine's operation to meet their unique requirements.

Tailored to User Preferences: Users can tailor the product to their preferences thanks to the model options' flexibility, which maximizes user satisfaction and experience overall.

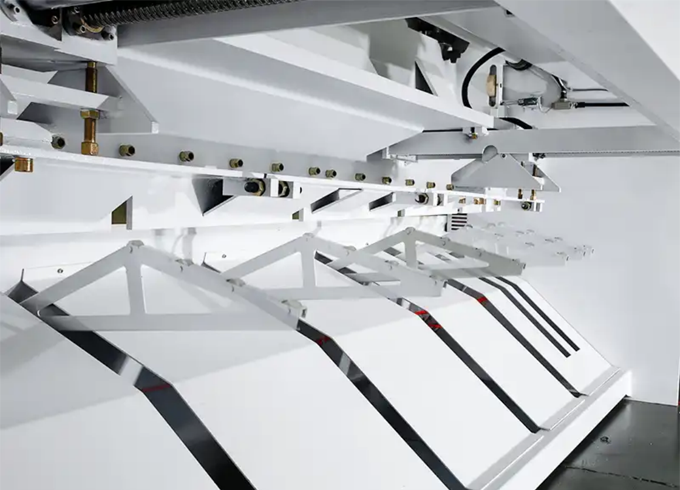

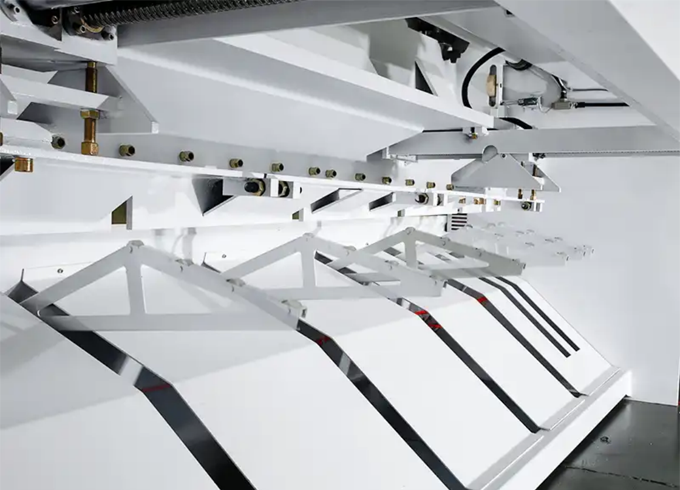

Pneumatic Rear Support

1. Material Support Stability:

In order to prevent sagging or distortion during shearing, the Pneumatic Rear Support guarantees stable material support.

2. Effective Management of Big Sheets:

The pneumatic back support, which keeps the material aligned and improves shearing efficiency, is especially helpful for large sheets.

3. Safety and Convenience for Operators:

The pneumatic rear support streamlines material handling, lessens operator physical strain, and improves safety throughout the shearing process.

Hydraulic Oil Cooling Device

1. Effective Temperature Management: Preserving Ideal Operating Conditions

2. Extended Equipment Lifespan: Avoiding Overheating to Extend Equipment Life

3. Improved Hydraulic System Performance: Reliable Performance in Various Uses

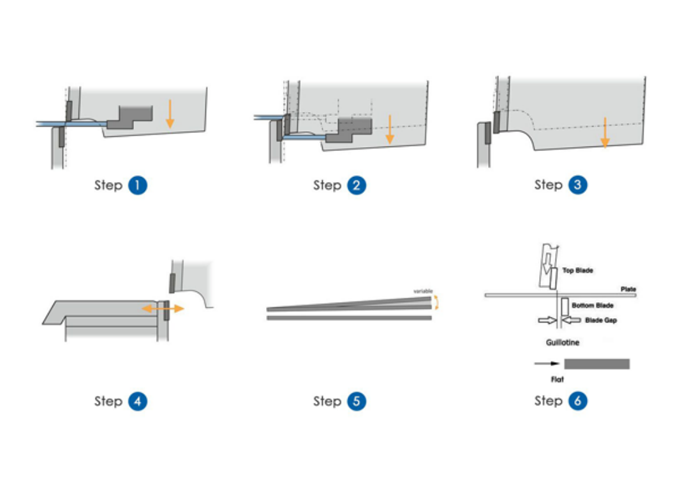

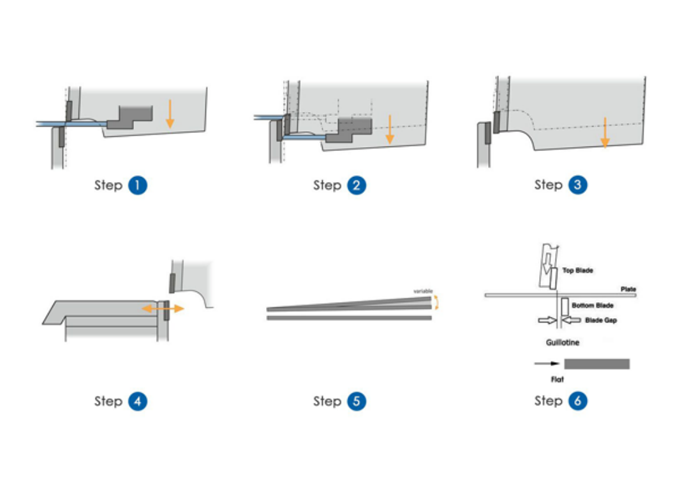

Principle of guillotine shearing machine

1. Accurate Cut Action:

By turning above the swing beam's lower edge, the upper blade starts the cut.

2. Silent Blade Dissociation:

Following cutting, there is little friction as the upper blade glides away from the bottom blade.

3. Versatility-Adjustable Clearance:

With the cutting gap eccentric, you can easily adjust the blade clearance to accommodate different material thicknesses while keeping accuracy.

4. Effective Shear Design for Riding:

Effectiveness across a range of material thicknesses is ensured by the design's low rake angle, which permits an effective riding shear approach.

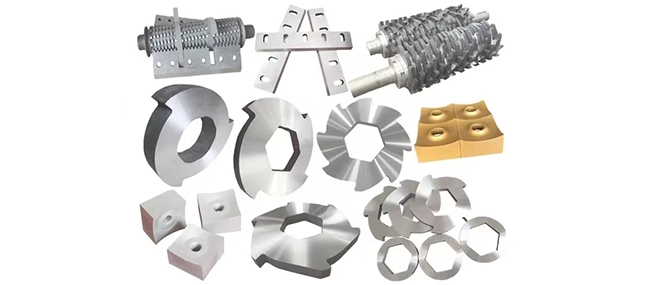

Processing Equipment of Q11K Guillotine Shearing Machine

We focus on every aspect of the machine and are dedicated to making the best machine tools possible for our clients.

English

English