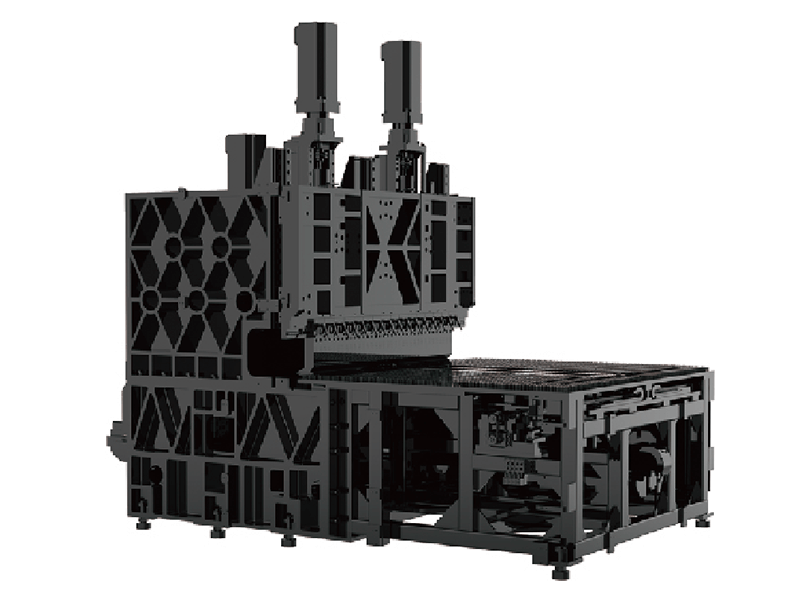

Servo Motor Drive in CNC Panel Bender

Without the need for hydraulic power, servo-electric panel benders offer a quick and precise bending solution. Productivity, accuracy, reproducibility, and dependability are all guaranteed by this technology.

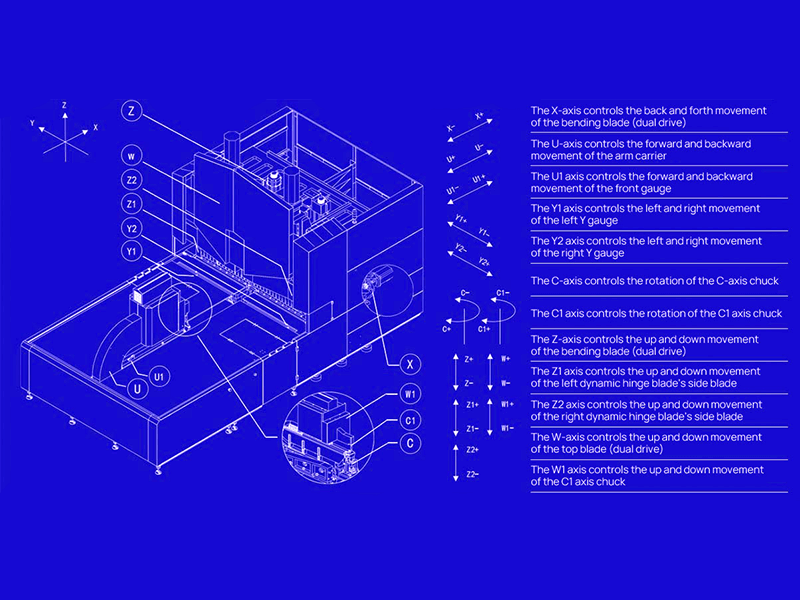

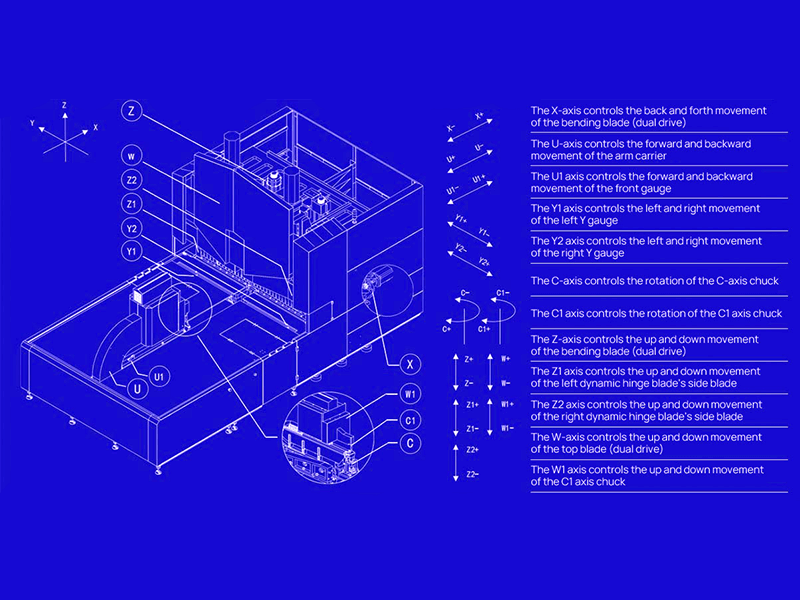

Control Axes in Automatic Panel Bender

The control system realizes a true nine-axis (15-axis) synchronous linkage, smooth bending action and high mechanical operation synergy.

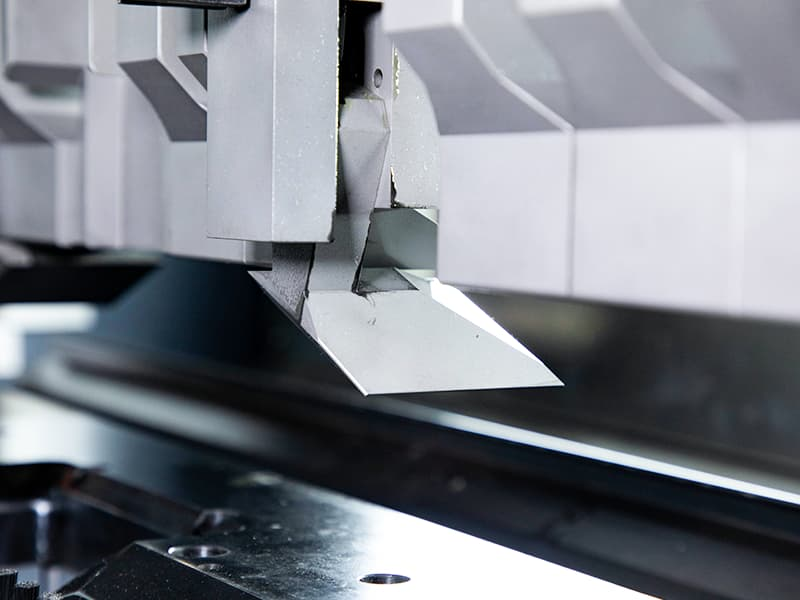

Pressure Arm in Panel Bender

The feeding method was awarded a utility model patent for its simplicity, convenience, ease of operation and safety

.

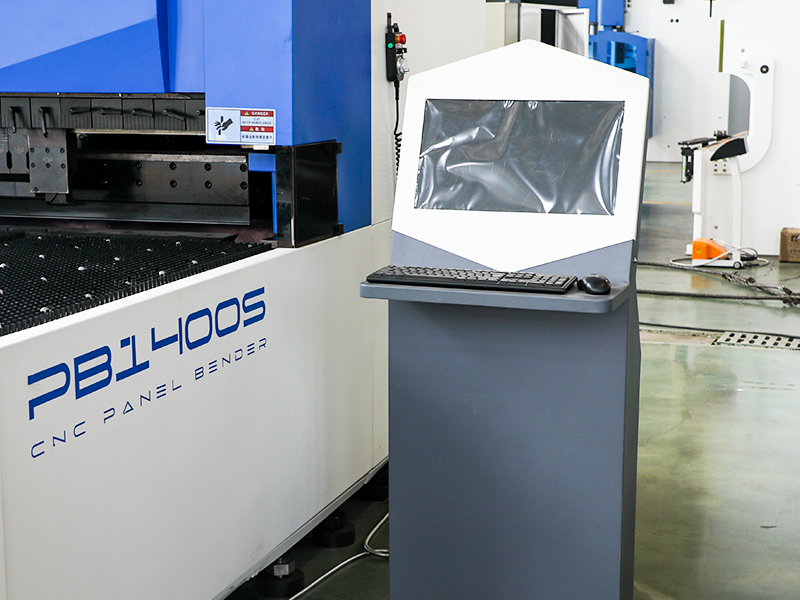

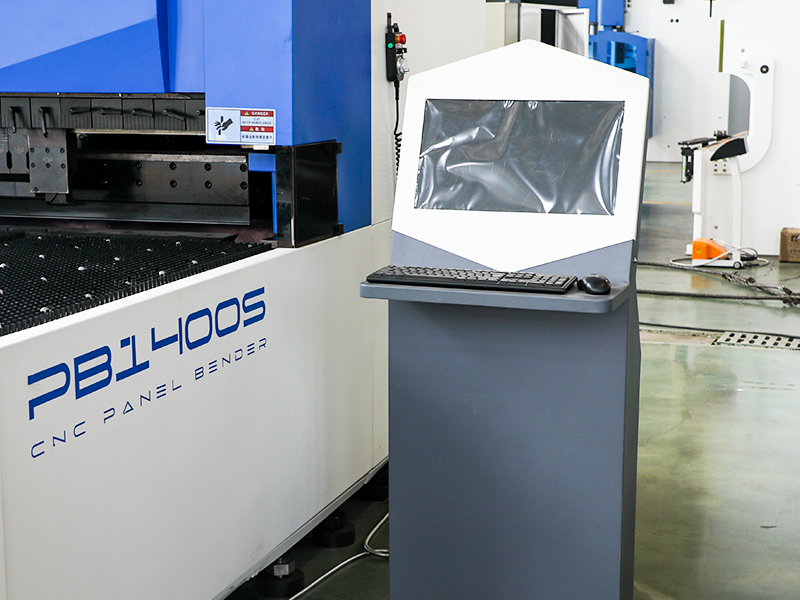

Console in CNC Panel Bender

The control system realizes a real nine-axis (13-axis) synchronous linkage, which ensures stable bending action and strong coordination of mechanical operation.

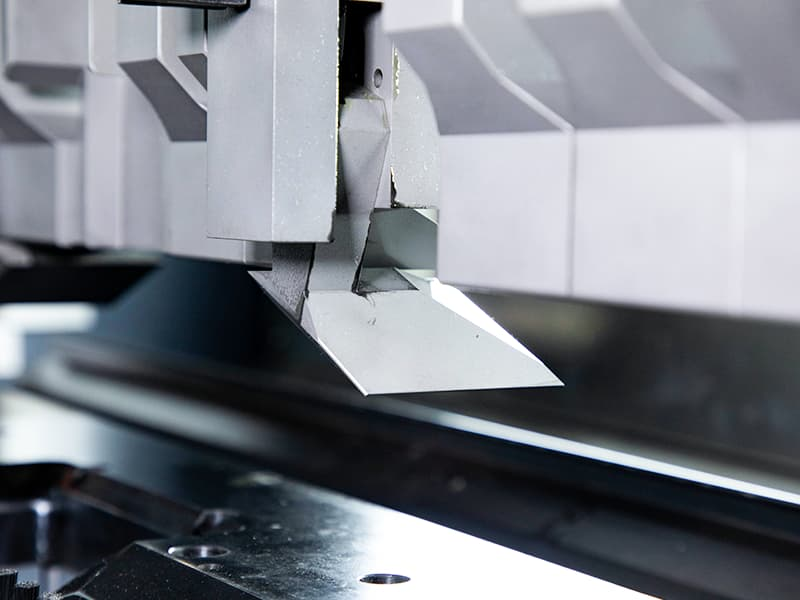

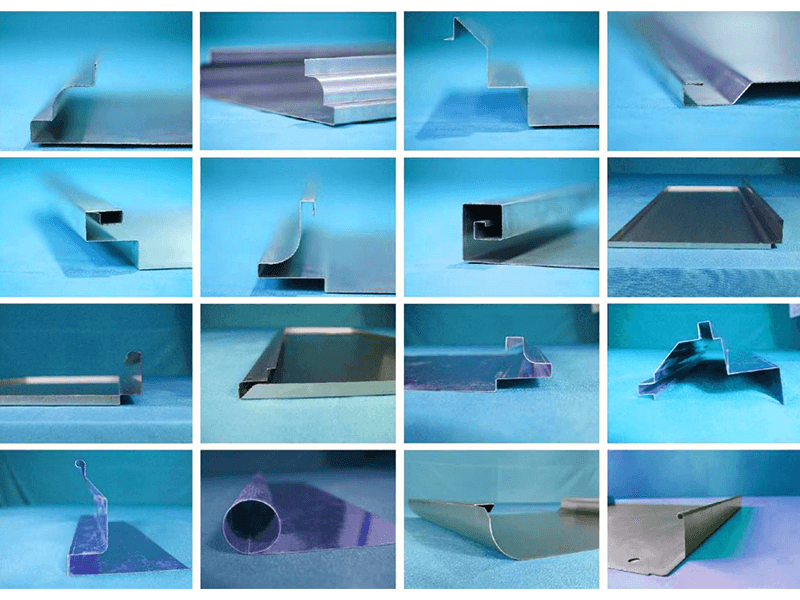

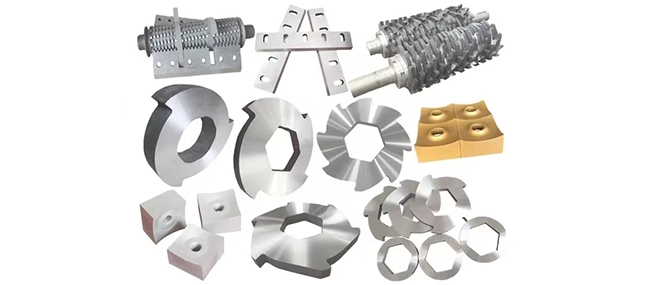

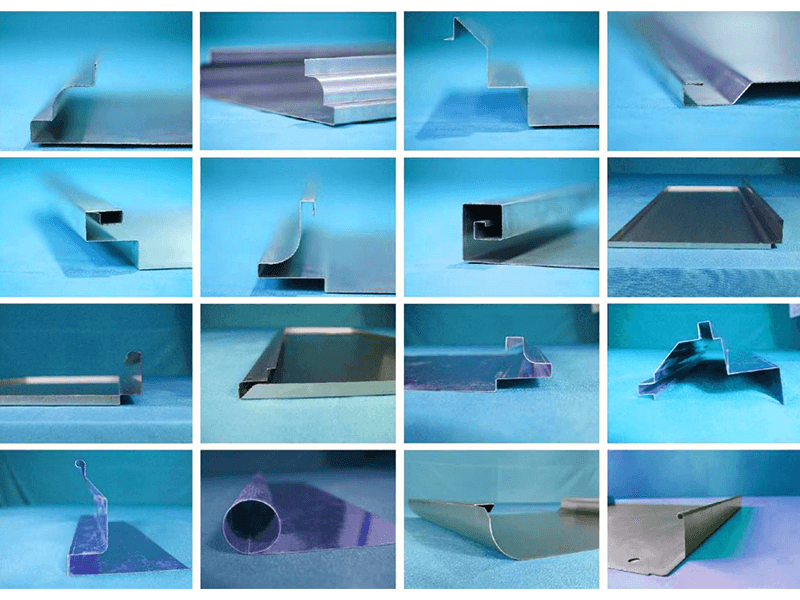

Tools in Automatic Panel Bender

Molds are not necessary for the design and production of complex shapes. Shapes having a range of angles—both right and non-right—that may be folded up or down as needed can be produced using this method.

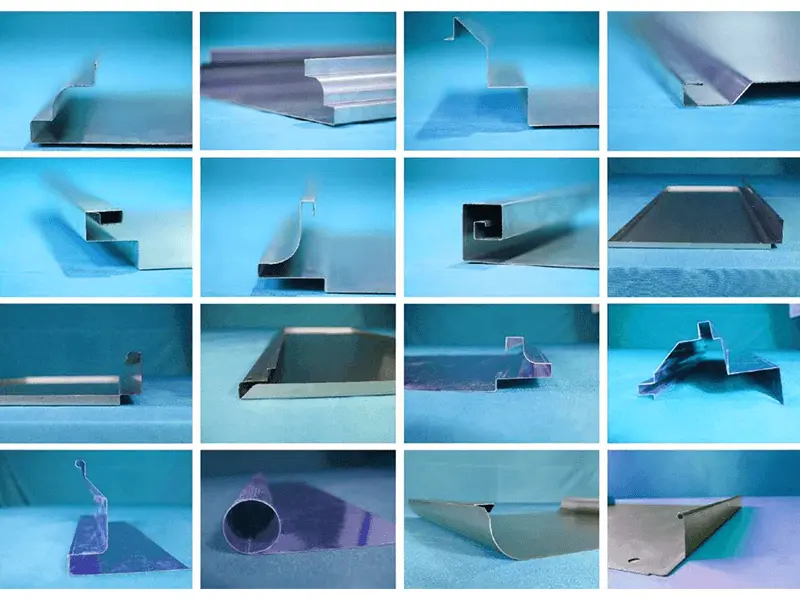

Bending Workpieces with Panel Bender

This technique is applicable to a wide range of materials, including stainless steel, cold rolled sheet and aluminum, to name a few.

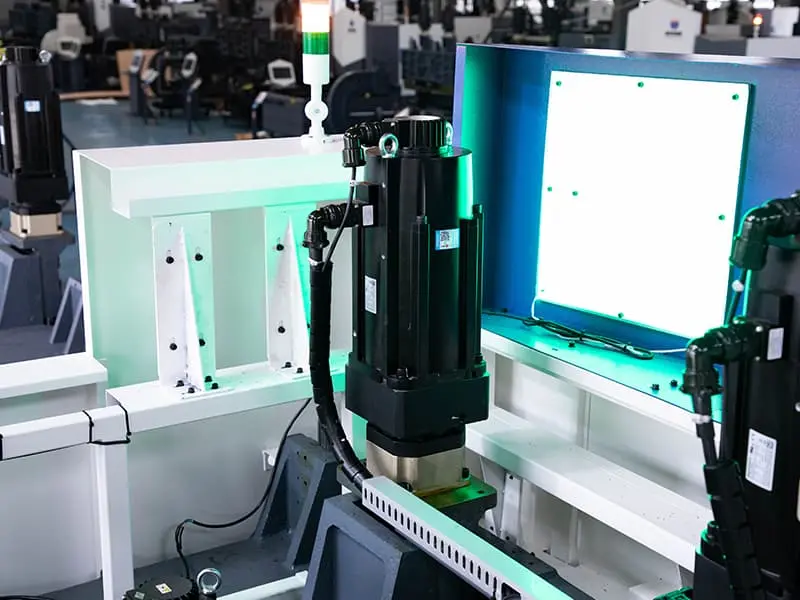

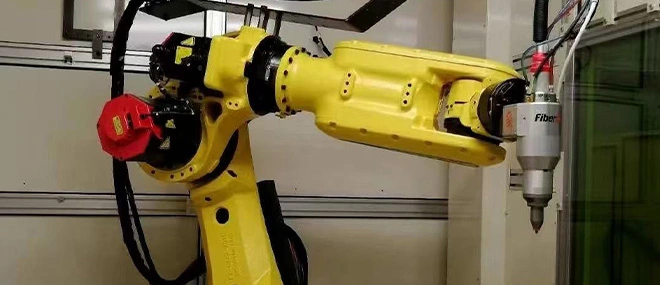

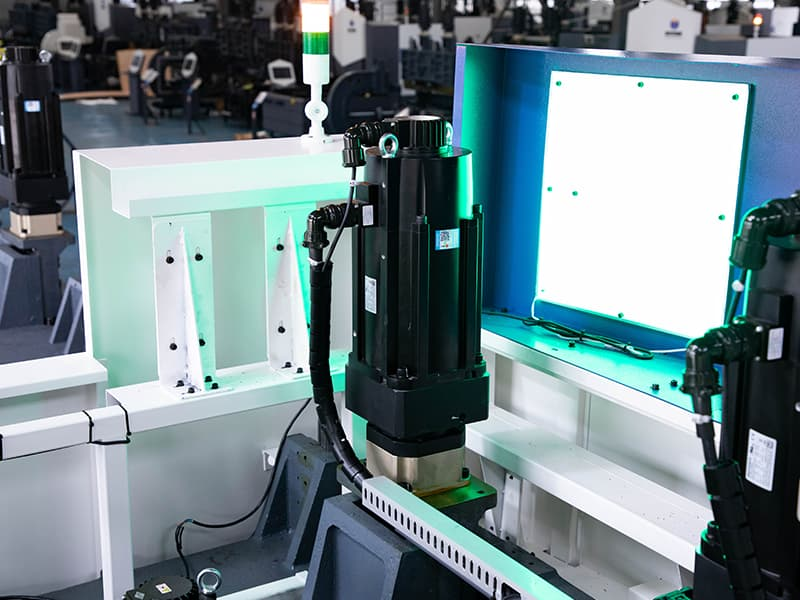

Servomotors in CNC Panel Bender

All movements are powered and regulated by servo motors.

Cast Iron Fuselage in Automatic Panel Bender

The fuselage is heat treated in a tempering furnace.

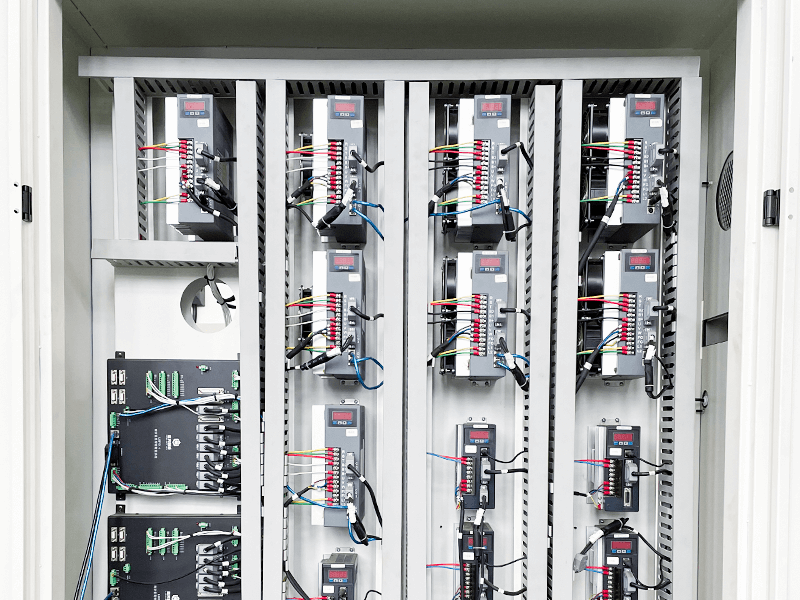

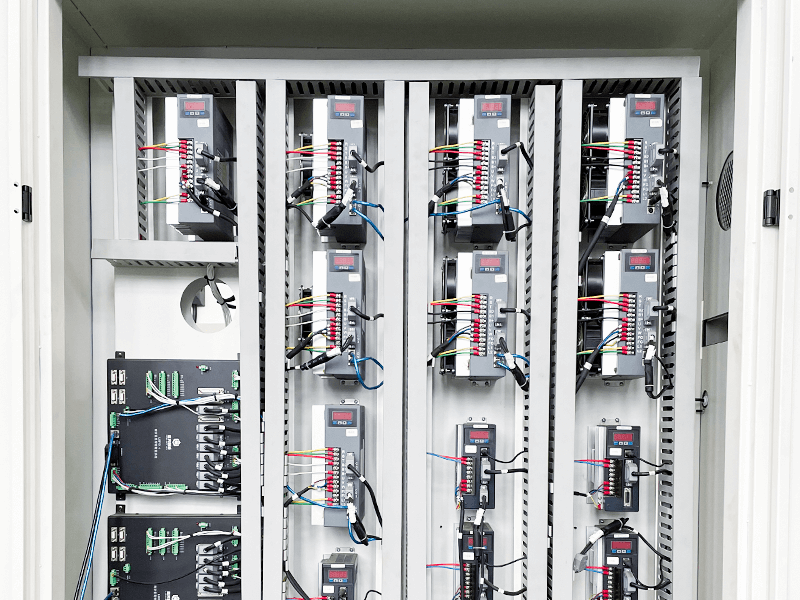

Electrical Components in Panel Bender

Imported electrical components are used to ensure electrical stability.

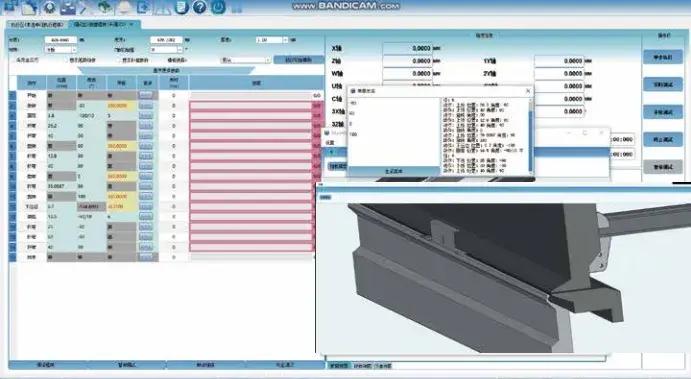

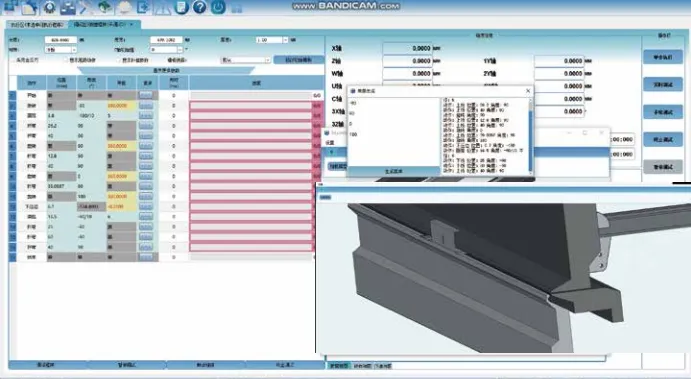

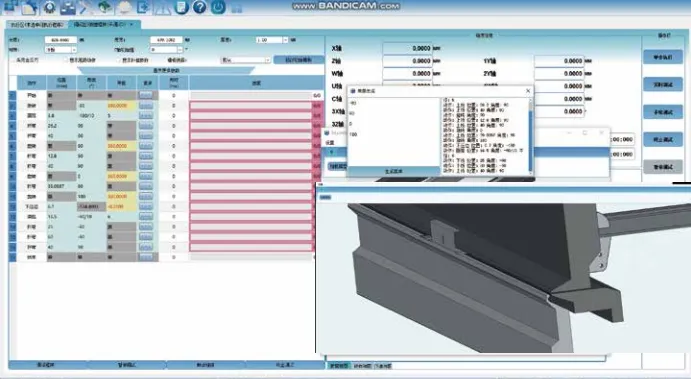

2D/3D Drawing Import in CNC Panel Bender

Easy 2D Graphic Programming: Our system has an easy-to-use 2D graphic programming interface that lets users enter precise bending parameters and automatically create bending programs.

Easy Input of Bending Parameters: Make programming easier by entering bending parameters straight into the 2D visual interface. This will speed up the creation of bending programs and enhance productivity.

Seamless Integration with 3D Drawings: Enhance versatility with the ability to import 3D drawings directly into the programming interface, providing comprehensive support for a more integrated and efficient workflow.

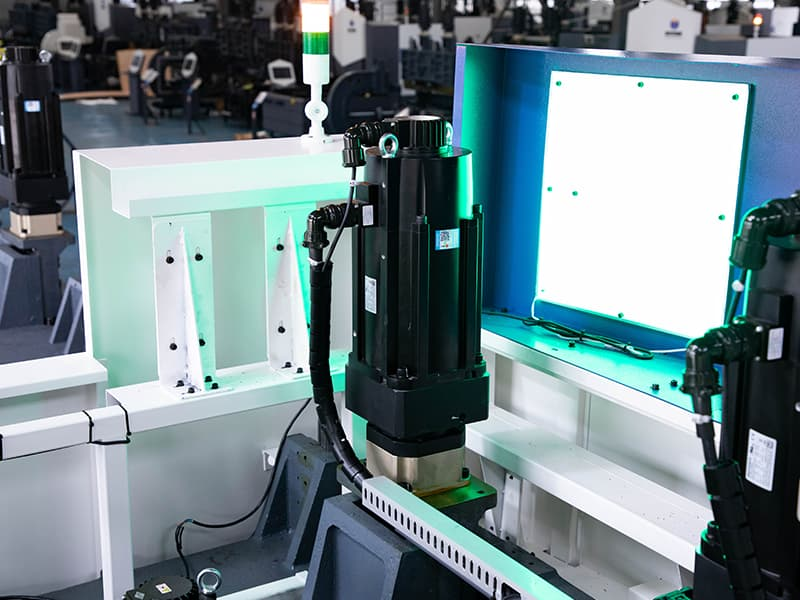

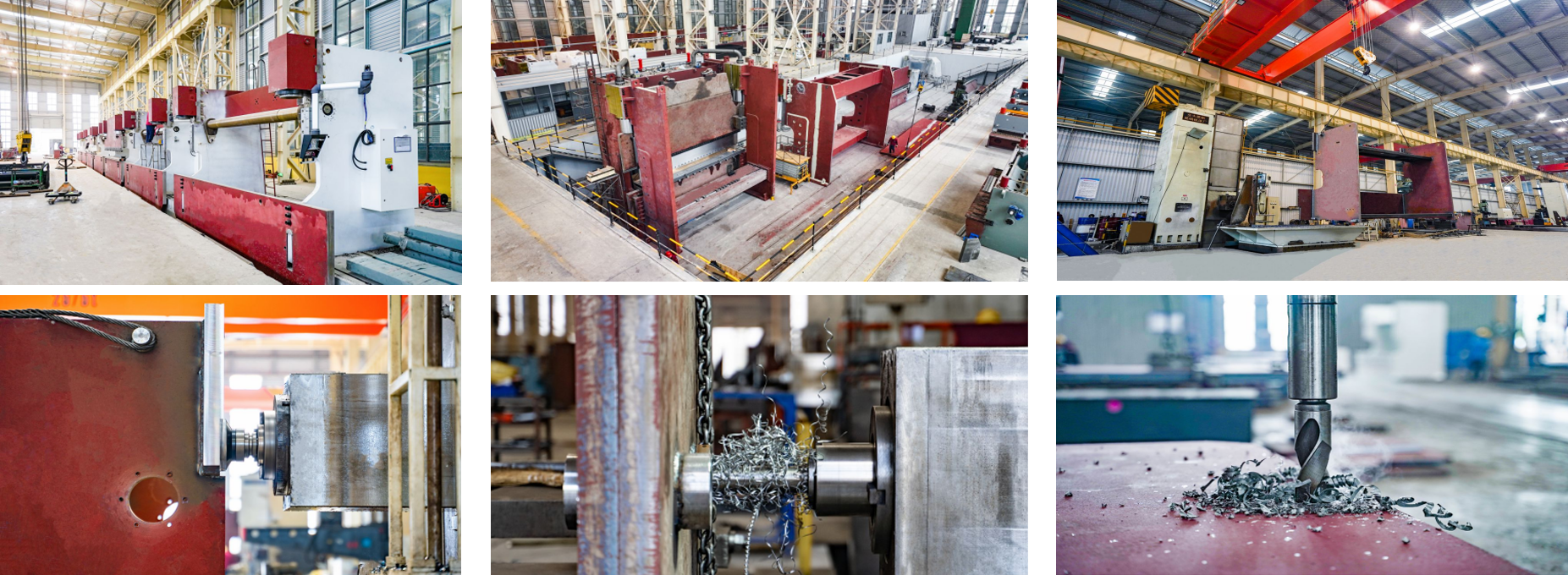

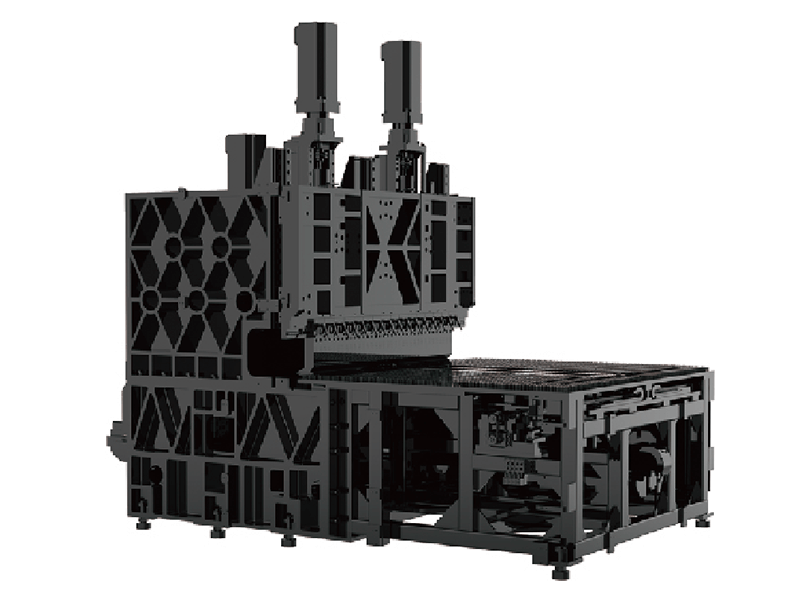

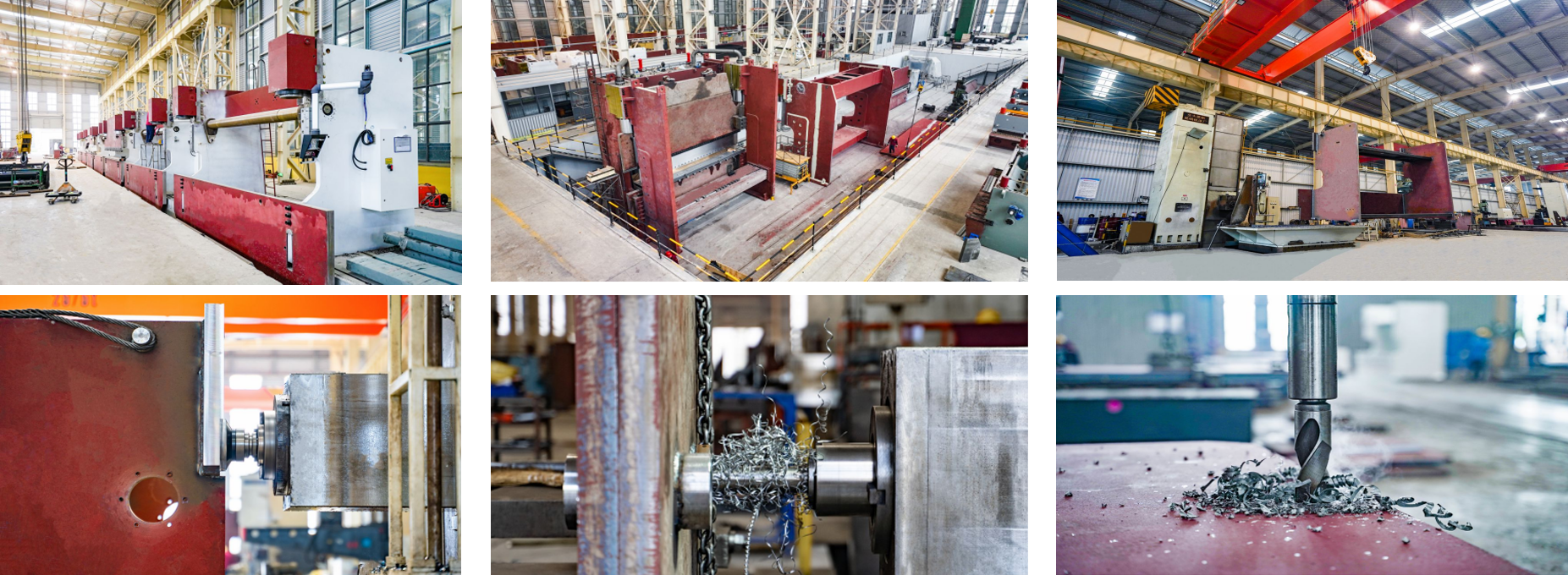

Machining Equipment in Panel Bender

Our Panel Bender exemplifies our manufacturing prowess, blending technology with craftsmanship.

This cutting-edge machine demonstrates our commitment to high-quality metal fabrication with precision and efficiency, solidifying our position as an industry leader.

English

English