- Home

-

Products

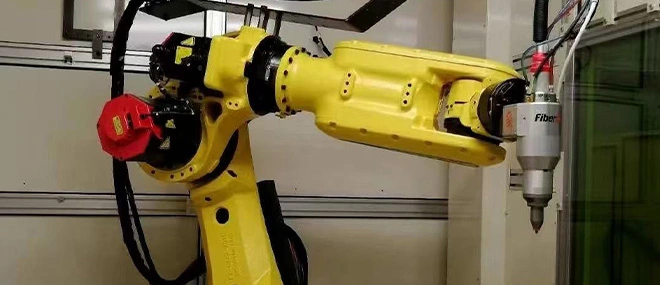

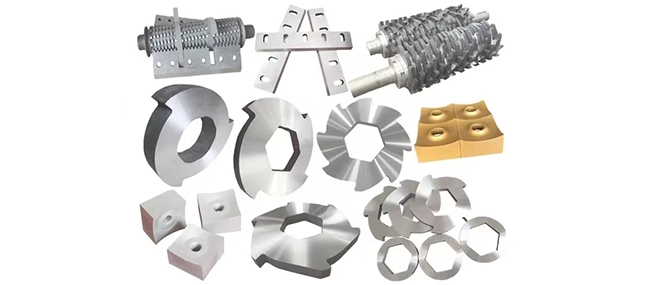

Laser Cutting Machine 3D Cutting Robotic Arm Automatic Loading and Unloading Laser Cutter Single Table Fiber Laser Cutting Machine Dual-use Fiber Laser Cutting MachineHydraulic Press C Frame Hydraulic Press APA C Frame Pneumatic Power Press APA Pneumatic Press Machine J21S Deep Throat Punching MachinePlate Rolling Machine W11F Asymmetric 3-Rollers Plate W11 3-Roll Plate Roller Machine W12 4-Rolls Sheet Metal Plate B W11S 3-Rollers Variable Geometry

- System & Solutions

- Production Process

- Company

- Support

- Contact

English

English