The most crucial components for dependable and effective molding are included in our C-frame hydraulic press solutions.LANGYE is a cutting-edge press designer, manufacturer, and service provider.

The goals of our research are quality, precision, and innovation. In actuality, a large number of clients worldwide have trusted our C-frame hydraulic presses.

C-Hydraulic Presses: Shearing of the Billet

The C-frame hydraulic presses in our Y41B series have a power range of 50 to 300 tons.

C-Frame Hydraulic Presses: Manufacturer of Shear

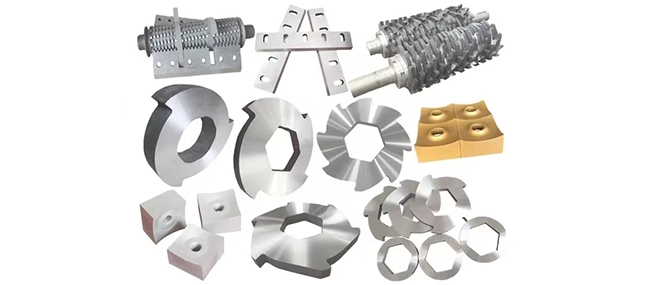

made especially to handle tasks like die cutting, molding, stamping, deep drawing, and more.

Shear Models for C-Frame Hydraulic Presses

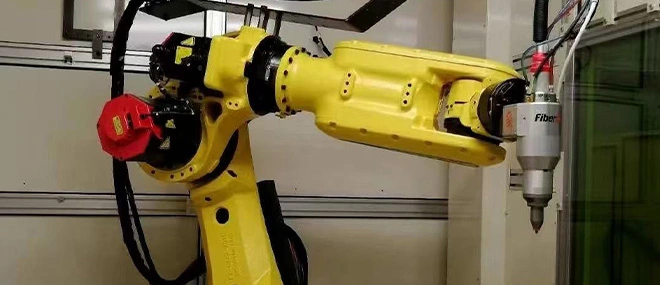

One of the many applications for the most recent generation of Y41B series C-frame hydraulic presses is the integration of these devices into automated manufacturing lines.

Standard Equipment

Japan's Mitsubishi

French electrical company Schneider Electric

Main Motor: Germany's Siemens Electric

Foot switches: Korea's KACON

Hydraulics: Germany's Bosch Rexroth

Oil Pump: Sunny, United States

Seals: Parker, USA

IE3 c high efficiency motor

Introduction to Configuration

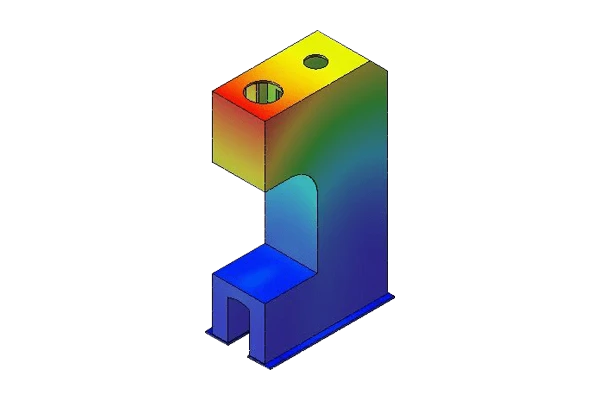

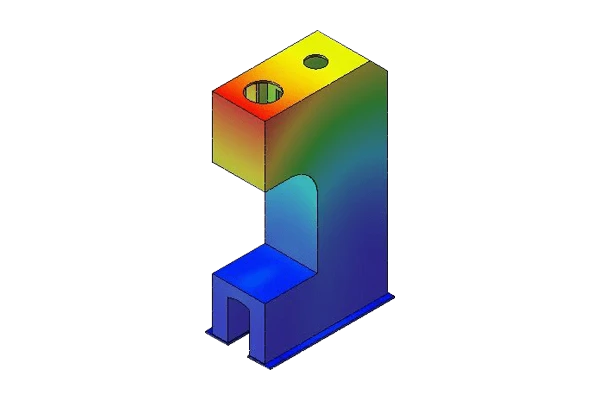

Finite Element Analysis and Stress Analysis

The linear static structures, stresses, and deformations of press brakes and laser cutting machine frames are analyzed using the CAE program SOLIDWORKS. As a result, FEA is applicable to transient modeling, complicated structures, extremely complex loads, and combinations of these.

Structure and Tables

Only S355JR steel is used in the electrically welded construction of Y41B type C-frame presses. To guarantee flawless parallelism and accuracy, they are machined and stabilized at the conclusion of the structural welding procedure. developed and calculated using finite elements. Despite everything, we consistently promise our exacting and superior standards. Mechanized bottom and upper C45E steel tables with DIN-650 recesses are included with these variants. Two 50 mm diameter cylindrical lateral guides on the upper table provide precise alignment, and it features a bimetallic cover that is easy to maintain and resistant to friction.

Cylinders and hydraulic units

The double-acting cylinders include anti-friction guides that require no maintenance and plungers that are chrome-plated. Cylinders with a square front and stroke end include a common anti-rotation device that makes adjusting the cylinder stroke simple.

electro-hydraulic unit with two speeds and automated deactivation at high speeds. fitted with a valve that lowers cylinder pressure. The most appropriate pressure signal for each pressing type can be adjusted thanks to the conventional side pressure switches.

They are outfitted with tons-reading glycerine meters.

Electrical Installation and Safety

In addition to a switch to set rapid or slow speed, the control panel features a switch that lets the user choose between manual, semi-automatic, or automatic operation. The hydraulic and electric motions are independent and redundant. For safety and maneuverability, they have self-control mechanisms and an extra safety block. It features photocell safety distances and proper operation verification and certification.

A low voltage electric pedal does the function.

Two side protection devices and a class IV safety light curtain at the front are used to assure safety.

They make it possible to add hydraulic ejectors or hydraulic pads. An instruction manual is included with them.

It conforms with and fulfills all of the fundamental EU standards for health and safety.

Technical Paraments of of C Frame Hydraulic Press

| Name Model | Unit | Y41B-4T | Y41B-6.3T | Y41B-10T | Y41B-16T | Y41B-25T | Y41B-40T | Y41B-63T | Y41B-100T | Y41B-160T | Y41B-200T | Y41B-250T | Y41B-315T |

| Nominal force | KN | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | Nominal force |

| Maximum working pressure of liquid | Mpa | 8 | 8 | 8 | 13 | 20 | 23 | 25 | 26 | 25 | 25 | 25 | 25 |

| Maximum opening height | mm | 390 | 450 | 500 | 550 | 600 | 700 | 800 | 800 | 900 | 900 | 900 | 900 |

| Maximum stroke of slider | mm | 200 | 250 | 300 | 350 | 350 | 400 | 500 | 500 | 500 | 500 | 500 | 500 |

| Slide down speed | mm/s | 45 | 45 | 45 | 45 | 45 | 49 | 35 | 25 | 20 | 20 | 20 | 20 |

| Slider return speed | mm/s | 75 | 85 | 75 | 75 | 100 | 85 | 68 | 54 | 59 | 70 | 70 | 70 |

| Deep Throat | mm | 160 | 220 | 220 | 280 | 280 | 300 | 320 | 320 | 325 | 325 | 325 | 325 |

| Working desk size | F.B. | mm | 420 | 420 | 480 | 480 | 550 | 600 | 600 | 600 | 600 | 600 | 600 | 800 |

| L.R. | mm | 460 | 460 | 550 | 550 | 700 | 800 | 800 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Height of working platform from ground | mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 800 | 800 | 900 |

| Blanking aperture | mm | 70 | 80 | 80 | 80 | 80 | 100 | 120 | 120 | 100 | 200 | 200 | 200 |

| Motor Power | KW | 2.2 | 3 | 4 | 4 | 5.5 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Machine size | F.B. | mm | 1080 | 1080 | 1220 | 1280 | 1370 | 1470 | 1500 | 1550 | 1650 | 1700 | 1700 | 1750 |

| L.R. | mm | 620 | 650 | 730 | 755 | 805 | 1250 | 1400 | 1400 | 1400 | 1600 | 1800 | 1800 |

| Height above ground | mm | 1725 | 1900 | 1990 | 2100 | 2250 | 2450 | 2650 | 2650 | 2760 | 2700 | 2700 | 2850 |

| Total weight (approximately) | T | 0.7 | 1 | 1.5 | 1.5 | 2 | 3 | 4.5 | 5 | 6.5 | 8 | 10 | 12 |

Customer Cases

English

English