Focus on small workpieces

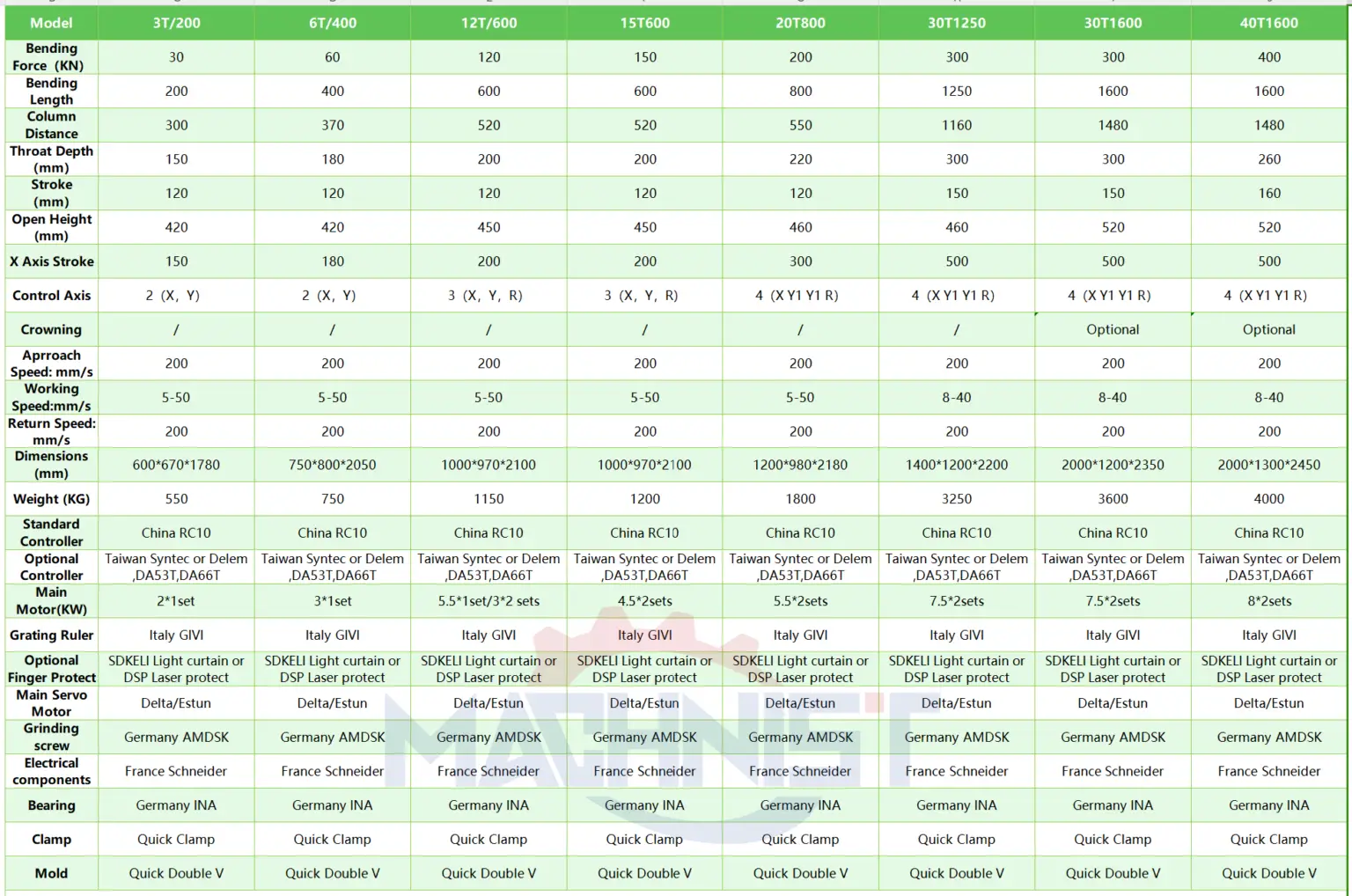

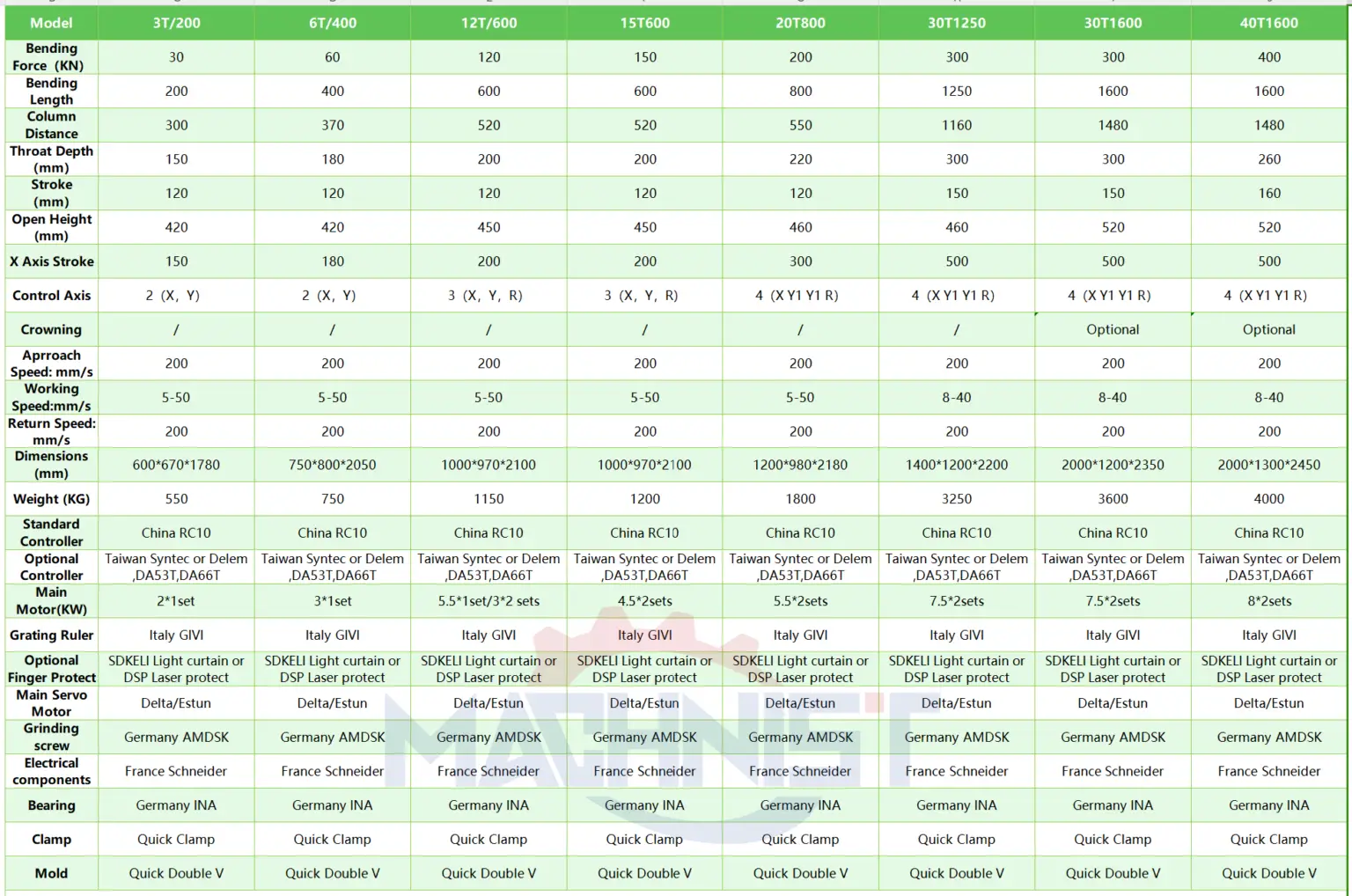

Technical Specifications of Auto Electric Press Brake

Parameters are for reference only and our company’s products will be updated without prior notice.

To obtain the latest configuration parameters, please contact us.

Features

This design is suitable for high-precision small workpieces,

represents a trend in future development.

01 energy-saving: 50%

High energy efficiency: Driven by a servo motor, it can adjust power output according to actual needs, avoiding the energy waste common in traditional hydraulic systems and improving energy utilization efficiency.

02 eco-friendly

No hydraulic oil pollution: Pure electric bending machines do not use hydraulic oil as a power transmission medium, unlike traditional hydraulic bending machines, which prevents environmental oil pollution and hydraulic oil leaks.

Decreased noise pollution: When compared to conventional hydraulic systems, pure electric bending machines usually generate lower noise levels, which lessens noise pollution in the workplace.

03 Higher precision

The Y-axis has a repeat positioning precision of ±0.01mm and a minimum movement setting unit of 0.005mm.

04 Fast speed

Approach and return speed of 200mm/s, working speed of 0-20mm/s.

05 Low maintenance cost

Because of its straightforward design, inexpensive upkeep, and reduced vulnerability to injury.

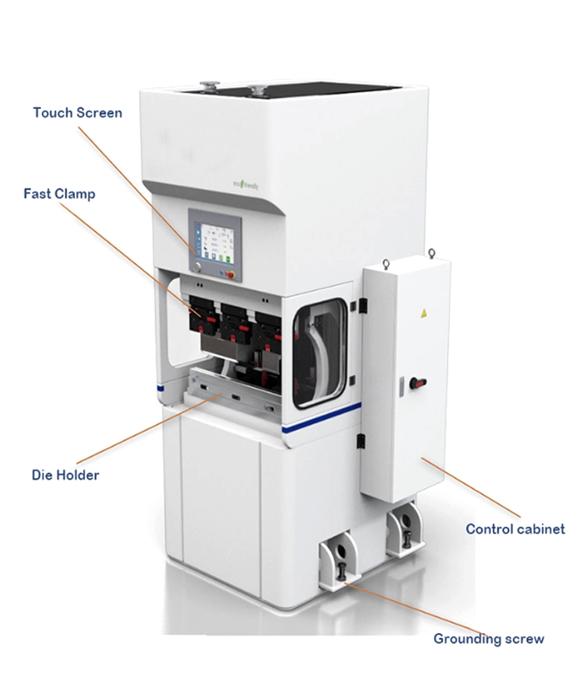

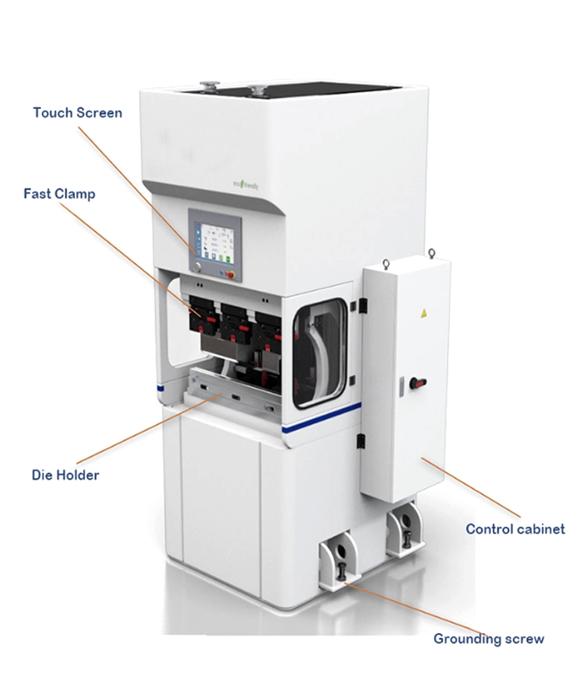

Main structure of full electric press brake

Frame

To meet the necessary load conditions, it uses a fully welded steel structure that is strong and rigid enough, and it simulates realistic load situations using finite element analysis. Annealing is used to remove any remaining tensions in the frame after welding.

Slider

This full electric press brake has a straightforward overall design that makes troubleshooting and maintenance easy. It uses an eccentric shaft-guided slide block structure.

Controller

The standard configuration utilizes a Chinese CNC bending system, providing flexible and user-friendly operation without the need for extensive operating experience. The visual touchscreen control allows for easy operation, and each axis adopts relative position recording of the origin, eliminating the hassle of origin disappearance and resetting. Optional configurations include the Taiwan Syntec 72BA or the Dutch Delem system.

Grating ruler

The Italian GIVI grating ruler, a fully closed-loop control system, with a repeat positioning accuracy of ±0.01mm.

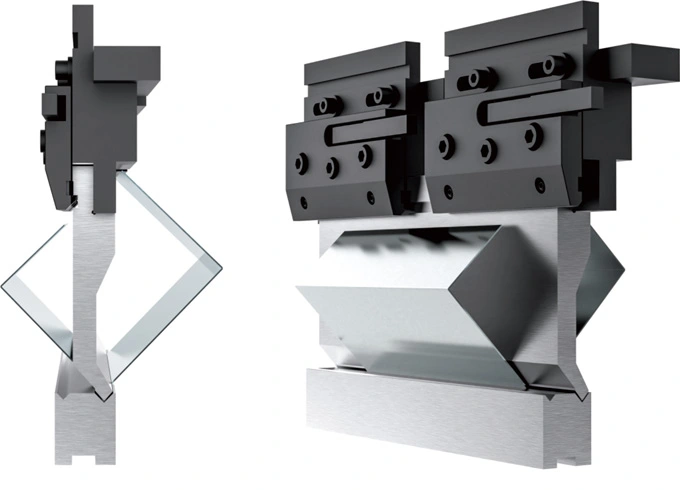

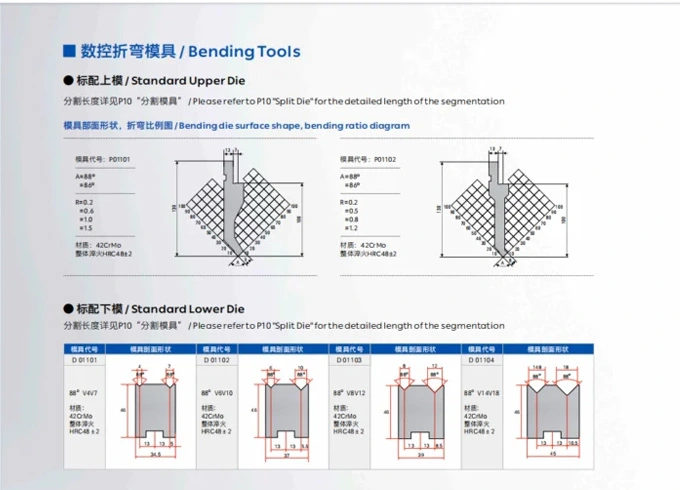

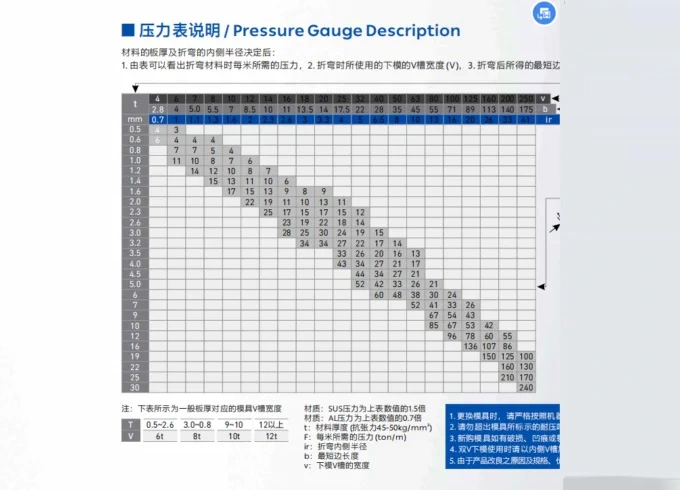

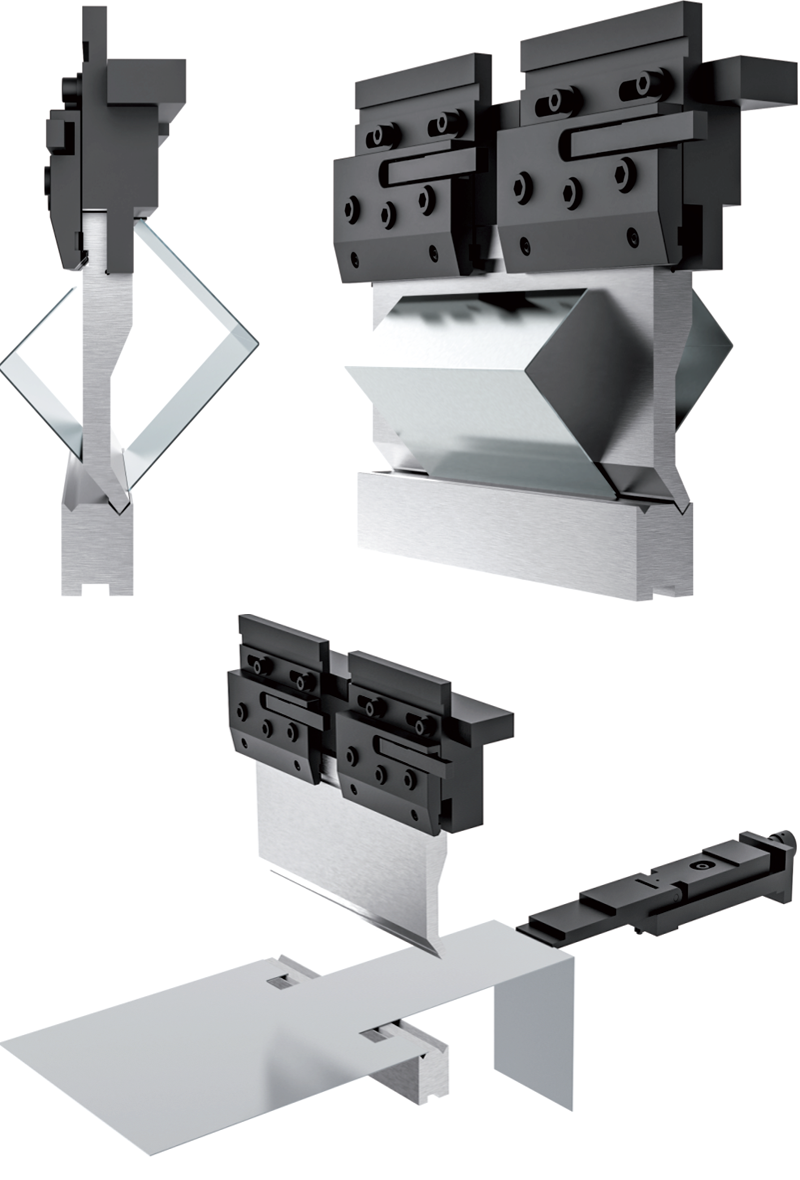

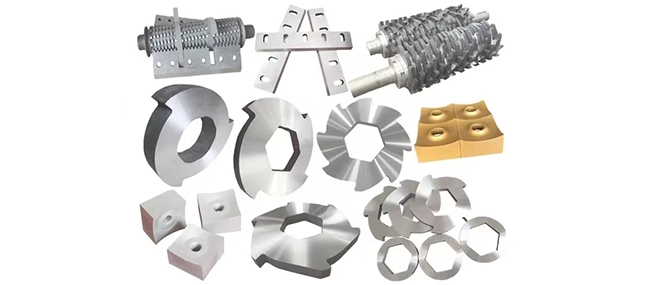

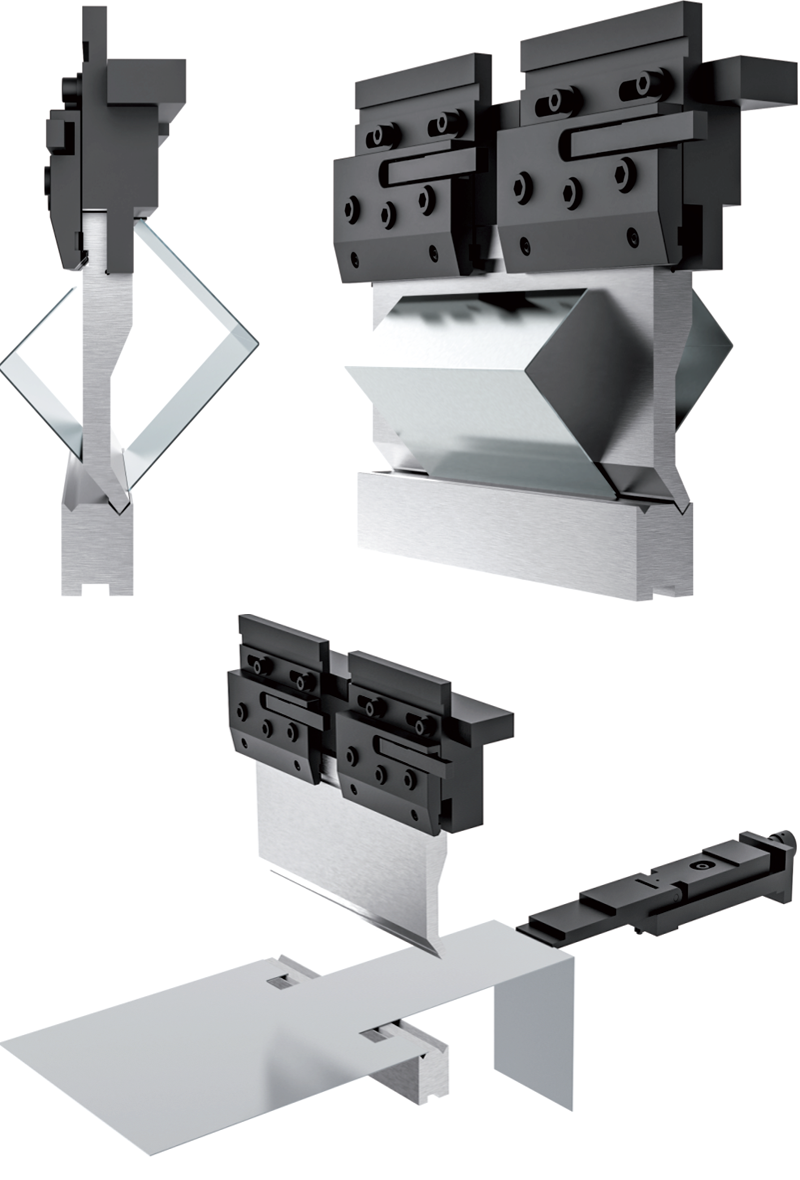

Punch & die

It utilizes standard CNC double-V molds, and custom molds can also be designed according to customer workpiece requirements.

Working Principle

The servo motor that powers the fully electric servo press brake reduces energy waste by converting electrical energy into mechanical energy. Using system signals, the servo may quickly and accurately modify the motor's output.

Controller system categorization

Controller

Standard Delem DA53t

Optional DA66t/DA69t,Esa640,etc

Advanced quick clamp

Extra large avoidance space

machnist machine tool

Deepened throat. Can be adapted to various non-standard molds.

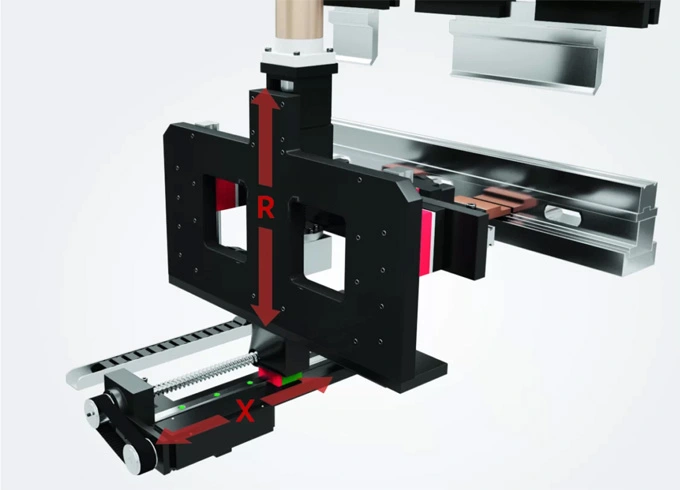

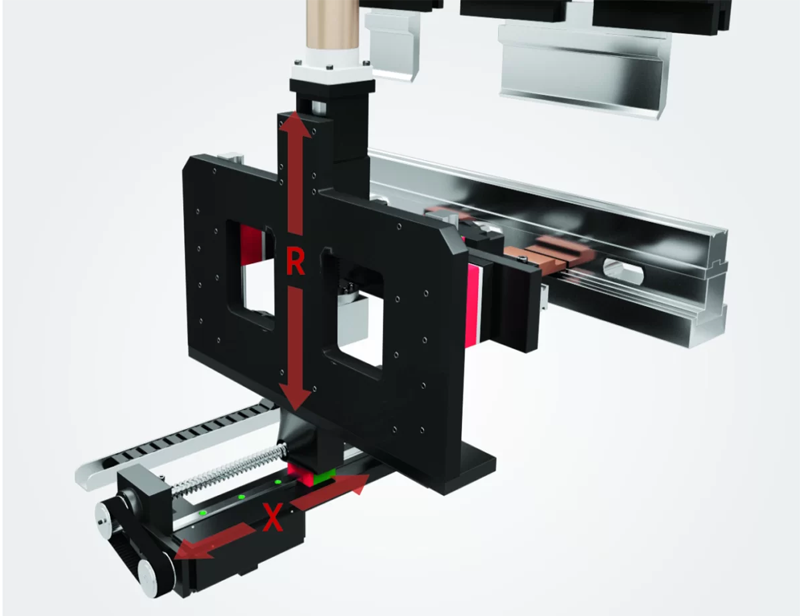

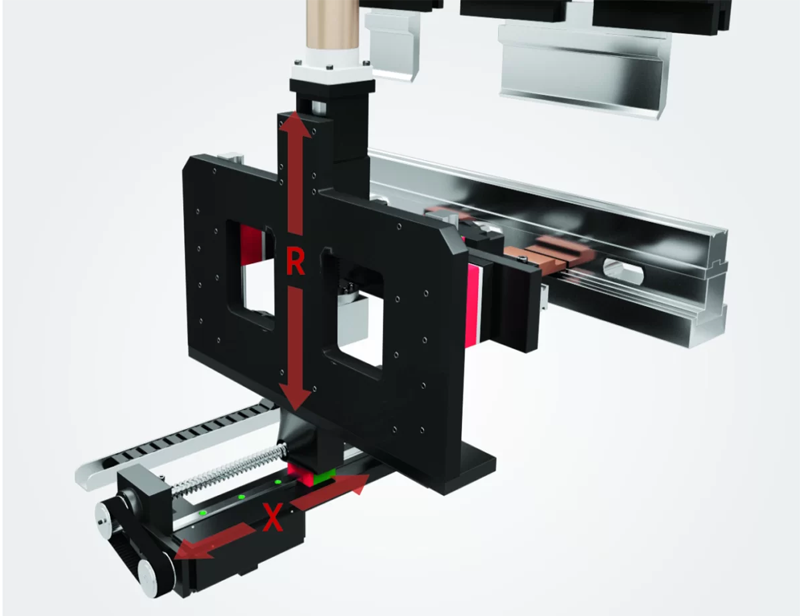

Backgauge

Standard 2-axis (X/R) backgauge, optional 4-axis (X/R/Z1/Z2).

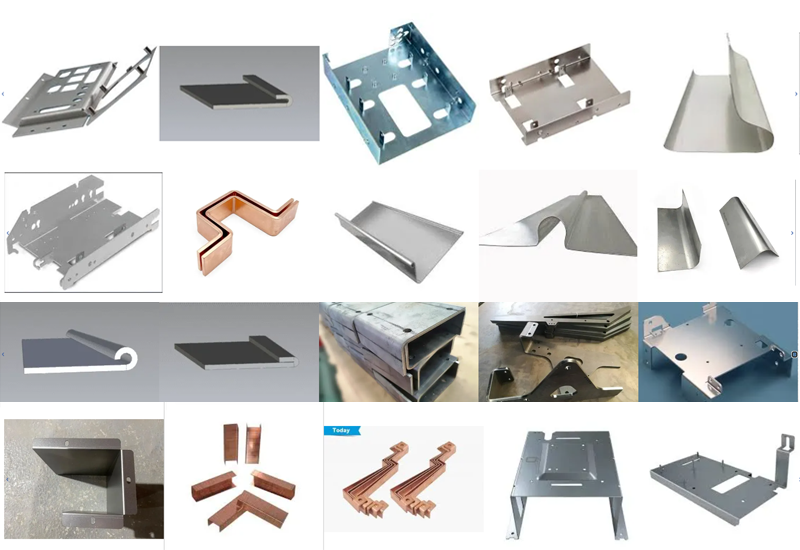

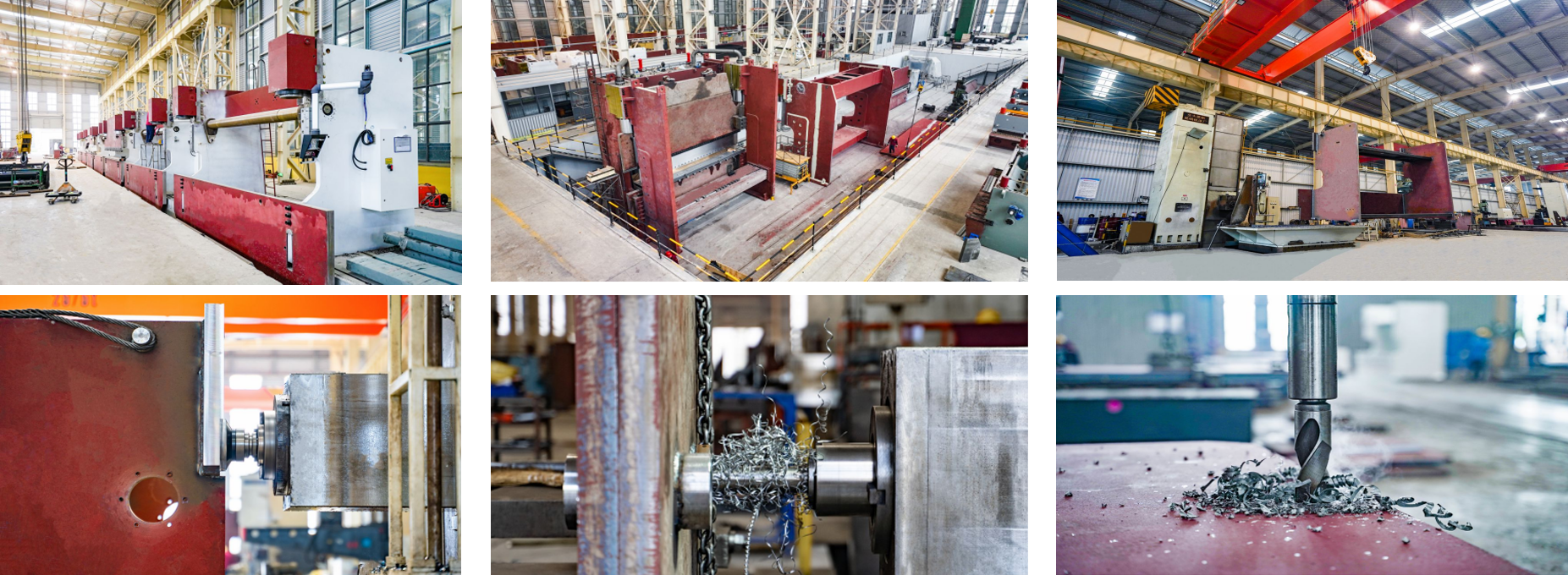

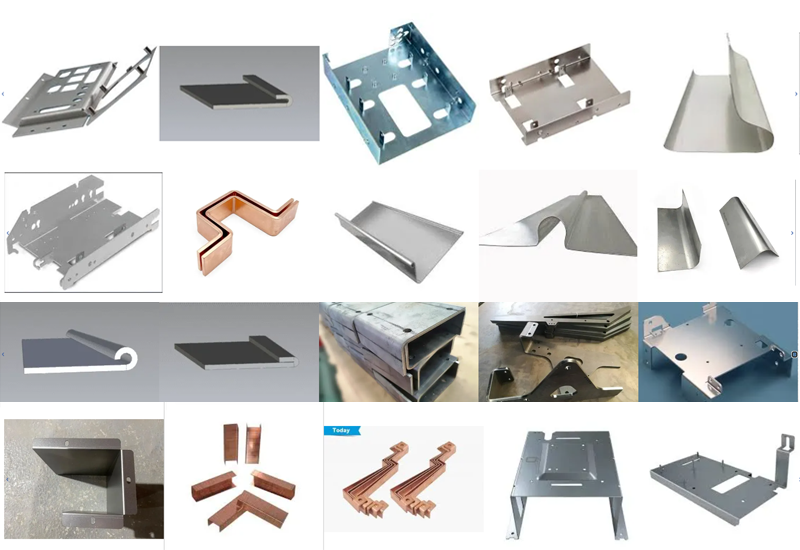

Processing Equipment

Our Hydraulic NC&CNC Bending Machines and Electric Bending Machines exemplify our manufacturing prowess, blending technology with craftsmanship.

This cutting-edge machinery demonstrates our commitment to quality metal fabrication with precision and efficiency, solidifying our position as an industry leader.

English

English