The JH21 series of single crankshaft presses, a workhorse for industrial presses that is considered industry standard, has been updated for the digital shop floor. These presses provide flexibility for enhanced performance and integration with the machine monitoring software package from LANGYE Press System, and they are made to work with a range of press automation options. We listened to what our customers had to say.

The Japanese wet clutch technology used in the APA series pneumatic punch press offers steady operation, excellent productivity, low noise levels, and minimal maintenance costs. Longer service life and a Japanese SHOWA hydraulic overload prevention pump are included. It is the most sophisticated and useful little stamping press that has been available in the market recently. Highly recommended for metal part fabrication.

The C-frame pneumatic power presses in our APA series have a power range of 25 to 400 tons.

made especially for tasks requiring die cutting, shaping, stamping, deep drawing, and other processes.

One of the many applications for the most recent generation of APA Series hydraulic presses is the integration of these devices into automated manufacturing lines.

Standard Equipment

Japan's Mitsubishi

French electrical company Schneider Electric

Main Motor: Germany's Siemens Electric

Foot switches: Korea's KACON

Hydraulics: Germany's Bosch Rexroth

Oil Pump: Sunny, United States

Seals: Parker, USA

IE3 c high efficiency motor

Introduction to Configuration

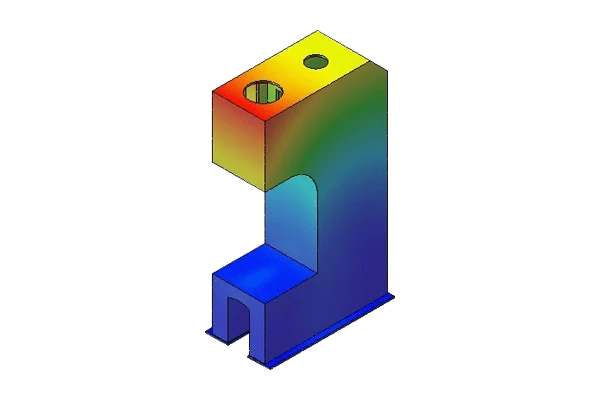

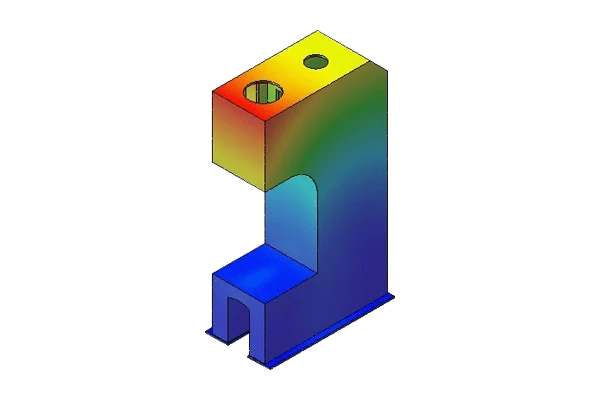

Stress analysis and finite element analysis

The linear static structures, stresses, and deformations of press brakes and laser cutting machine frames are analyzed using the CAE program SOLIDWORKS. As a result, FEA is applicable to transient modeling, complicated structures, extremely complex loads, and combinations of these.

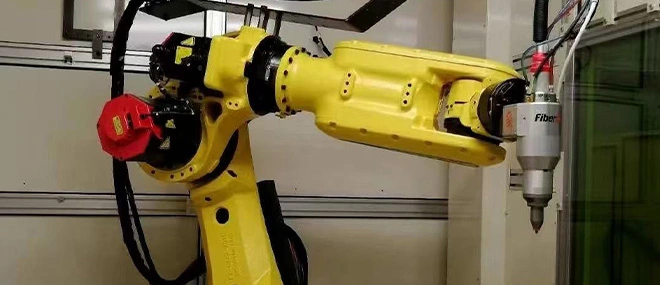

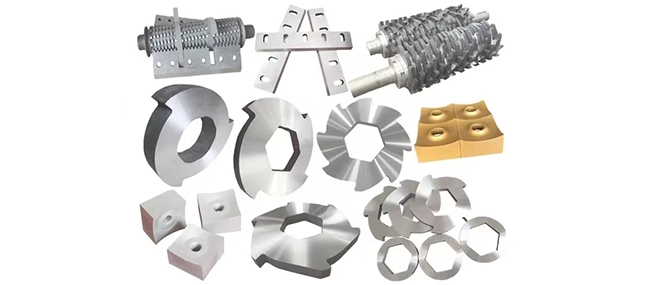

Structures and Tables

Langye has made significant investments in importing the most cutting-edge production equipment from around the globe, including Japanese Toshiba CNC machining centers, German Gleason grinding machines, German Liebherr hobbing machines, and twelve Italian PAMA CNC boring and milling machines.

Wolde produces over 85% of the mechanical components for JH21 series C-type presses because to its robust production capability and top-notch production equipment.

From structural building to final assembly, JH21 adheres to the highest Japanese JIS1 standard, featuring a compact design, superior configuration, dependable operation, and an extended service life.

Features

VSR (Vibration Stress Relief) or tempered steel welded body with excellent stiffness, stability, and precision.

To reduce noise and impact, the weight of the slider and punch is balanced by pneumatic double balancing cylinders.

After being high-frequency hardened, the crankshaft is ground.

Long, rectangular, six-sided walkway with a bronze plate surface.

Crankshaft arranged vertically with a compact structure.

Imported safety duplex valve and PLC control.

Multi-plate friction clutch and brake in a wet combination.

protection against hydraulic overload.

Electrical installation and safety

The control panel features a switch to choose between fast and slow speed, as well as a switch to choose between manual, semi-automatic, or automatic work modes. The hydraulic and electric motions are independent and redundant. For safety and maneuverability, they have self-control mechanisms and an extra safety block. It features photocell safety distances and proper operation verification and certification.

A low voltage electric pedal does the function.

Two side protection devices and a class IV safety light curtain at the front are used to assure safety.

They make it possible to add hydraulic ejectors or hydraulic pads. An instruction manual is included with them.

It conforms with and fulfills all of the fundamental EU standards for health and safety.

Technical Paraments

| Items | Unit | APA-15A | APA-25A | APA-35A | APA-45A | APA-60A | APA-80A | APA-110A | APA-160A | APA-200A | APA-260A | APA-315A | APA-400A |

| V | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H |

| Capacity | Ton | 15 | 25 | 35 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | 315 | 400 |

| Rated Tonnage Point | mm | 1 | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 | 8 |

| Stroke of slide | mm | 60 | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 | 300 |

| Stroke/min | Variable | S.P.M | 120-180 | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 35-90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-40 | 40-50 | 20-35 |

| Fixed | S.P.M | 130 | 110 | 85 | 75 | 65 | 65 | 50 | 35 | 35 | 30 | 30 | 30 |

| Max Die Height | mm | 200 | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 500 | 550 | 550 |

| Die Height Adjustment | mm | 50 | 50 | 55 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | 120 | 120 |

| Slide Area | mm | 300×230×50 | 470×250×50 | 520×285×50 | 560×300×60 | 700×400×70 | 770×420×70 | 910×470×80 | 990×550×90 | 1130×630×90 | 1130×700×100 | 1130×700×100 | 1050×840×95 |

| Bolster Area | mm | 680×300×70 | 680×300×70 | 800×400×70 | 850×440×80 | 900×500×80 | 1000×550×90 | 1150×600×110 | 1250×800×140 | 1400×820×160 | 1500×840×180 | 1500×840×200 | 1800×950×200 |

| Shank Hole Size | mm | Ø38.1 | Ø38.1 | Ø38.1 | Ø38.1 | Ø50 | Ø50 | Ø50 | Ø65 | Ø65 | Ø65 | Ø65 | Ø65 |

| Main Motor | KWXP | 2.2×6 | 4×4 | 4×4 | 5.5×4 | 5.5×4 | 7.5×4 | 11×4 | 15×4 | 18.5×4 | 22×4 | 30×4 | 37×4 |

| Capacity Of Die cushion | Ton | — | — | 2.3 | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | 14 | 14 |

| Stroke Of Die cushion | KW | — | — | 50 | 50 | 70 | 70 | 80 | 80 | 100 | 100 | 100 | 100 |

| Die Cushion Effective Area | Ton | — | — | 300×230 | 300×230 | 350×300 | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | 810×480 |

| Air pressure | Kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Overall Dimensions | L×R | mm | 740 | 840 | 900 | 950 | 1000 | 1170 | 1290 | 1390 | 1680 | 1850 | 1850 | 2090 |

| F×B | mm | 1264 | 1334 | 1384 | 1584 | 1604 | 1779 | 1904 | 2324 | 2624 | 2799 | 2799 | 2854 |

| H | mm | 2098 | 2179 | 2348 | 2525 | 2808 | 3040 | 3224 | 3600 | 4058 | 4430 | 4450 | 4615 |

Customer Cases

English

English