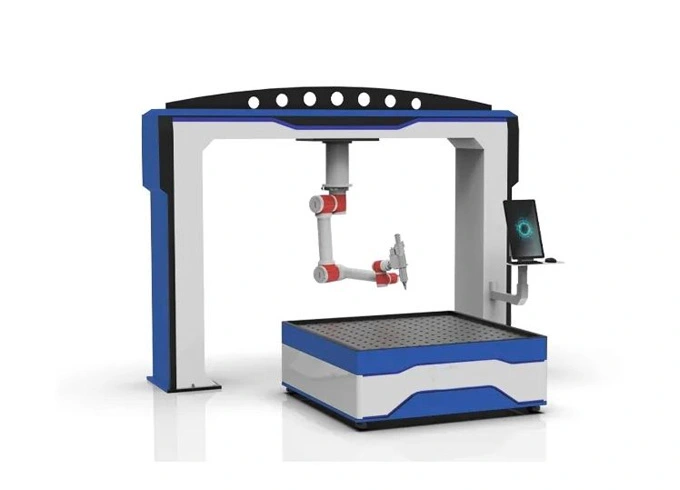

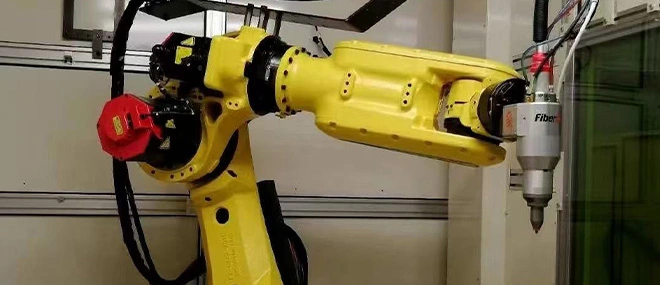

Details of 3D Cutting Robotic Arm

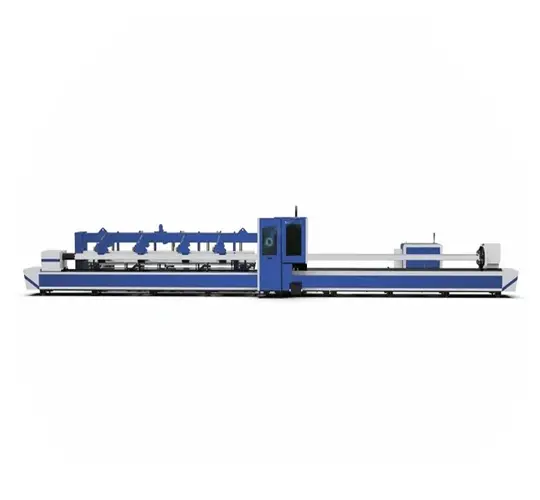

Advantages of Sheet and Tube Laser Cutting Machine with Exchange Platform and Cover

High Precision:

High levels of cutting precision are provided by fiber laser cutting machines, guaranteeing burr-free edges and better product quality.

Ease of Operation:

The expertise requirements for operators are decreased by the user-friendly interface that modern control systems offer.

Cost Savings:

Labor expenses are decreased via automation, and overall production costs are further reduced by the rapid cutting speed and minimal maintenance requirements.

High Flexibility:

Capable of cutting a wide range of materials and thicknesses, satisfying a variety of manufacturing requirements and providing a multitude of applications.

High Safety:

Because of its many safety features, the equipment improves worker safety by lowering the dangers associated with manual tasks.

Material Waste Reduction:

Optimized software nesting features and high-precision cutting capabilities optimize material use and minimize waste.

Environmentally Friendly and Energy Efficient:

Environmental protection regulations are met by the laser cutting process since it uses little energy, produces little noise, and produces little wastewater or waste gas.

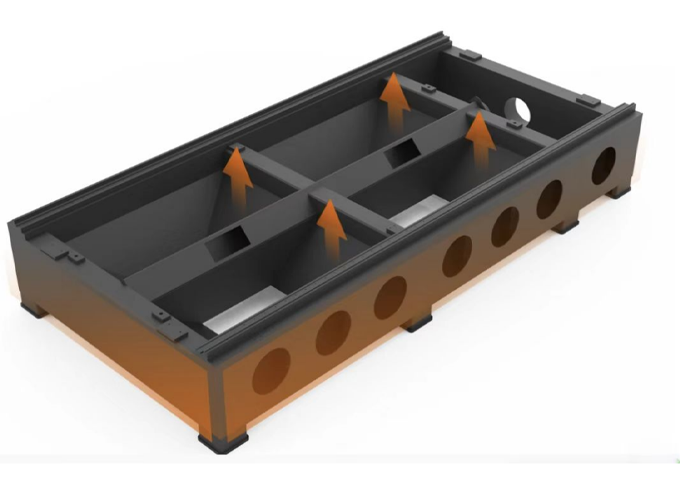

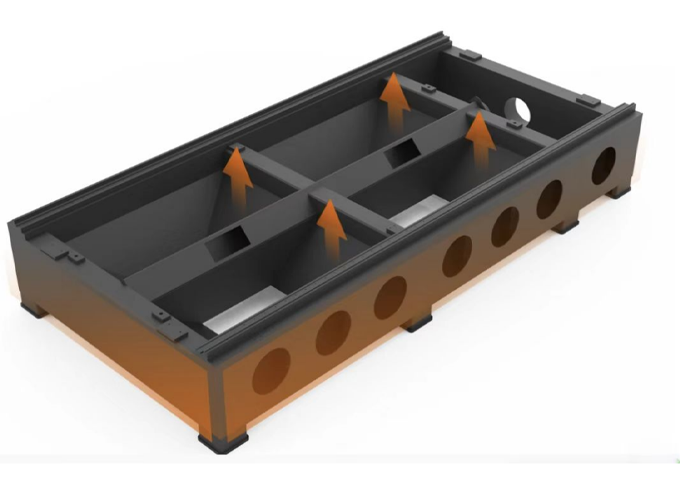

Machine Bed

Stability is ensured by the sturdy construction bed, which is welded from 10mm steel plates.

The entire machine is heat-treated and quenched at high temperatures, ensuring that it won't deform for 20 years.

Control System

The fiber laser cutting program Cypcut was developed only in China. It was created especially to maximize the efficiency of fiber laser cutting equipment.

Cypcut cutting software offers exceptional performance along with simple debugging and installation. Additionally, it allows for power-based speed modification, giving consumers even more freedom.

The program also has a strong cutting process database and independent import linear speed settings.

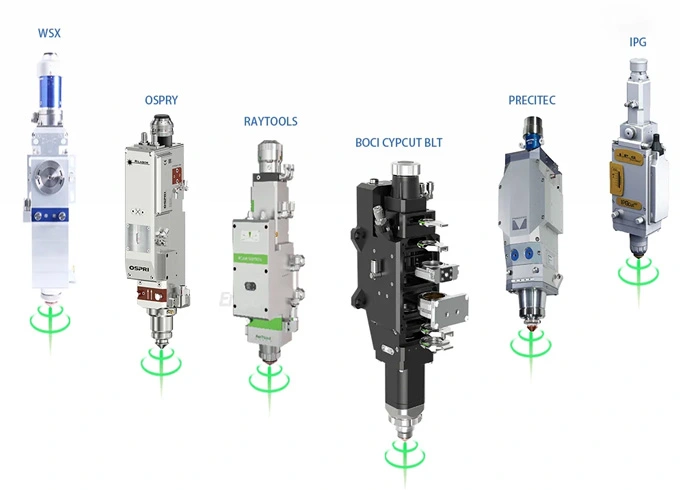

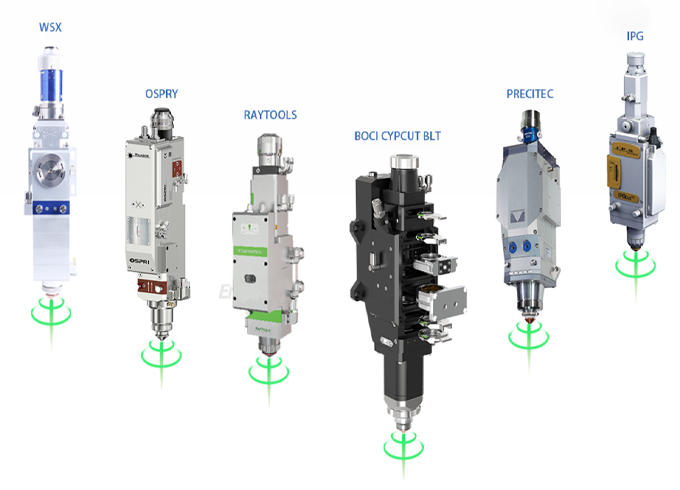

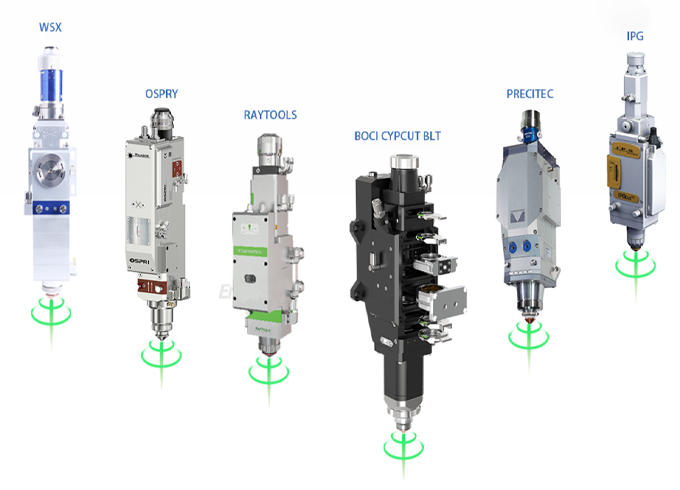

Cutting Head

We recommend these high-quality cutting heads. The standard Configuration is Raytool. Using BM111E as an example.

EtherCAT-based communication and autofocus control.

Four-color LED bulbs are used to monitor status.

Improved optical setup and a smooth gas circuit.

Up to 3.3KW of laser power can be supported by a D30mm combination lens.

The collimation lens is additionally protected by the top cover glass.

To make replacement easier, use a drawer-style cover glass holder.

Common interfaces for QBH/QD (LLK-D) to operate with various fiber lasers.

Fiber Laser Source

We use Raytool or MAX lasers as our usual setups. Their advantages over the German IPG fiber lasers are substantial when it comes to mid-to-low power.

The Wuhan Hanli water chiller is part of the basic setup.

High Power Density with Flat-top Distribution

High Beam Spot Concentricity

Fiber Core Diameter Optional

QBH or LOE Output

High Level Vertical Integration

Water Chiller

With functions including water level protection, flow protection, overheating alarm, and other safety alert alerts.

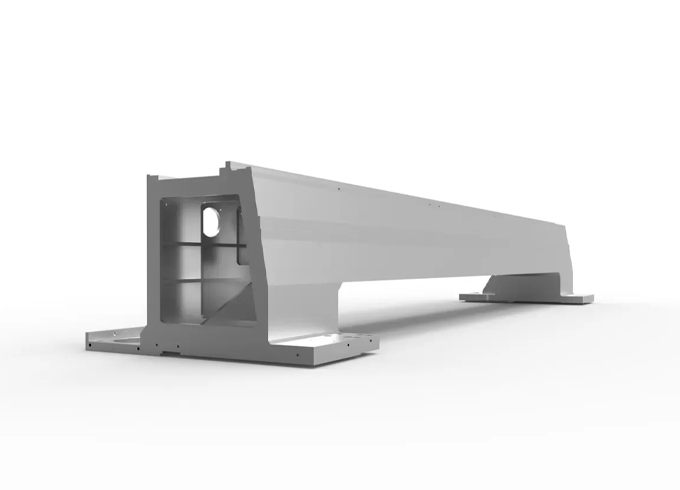

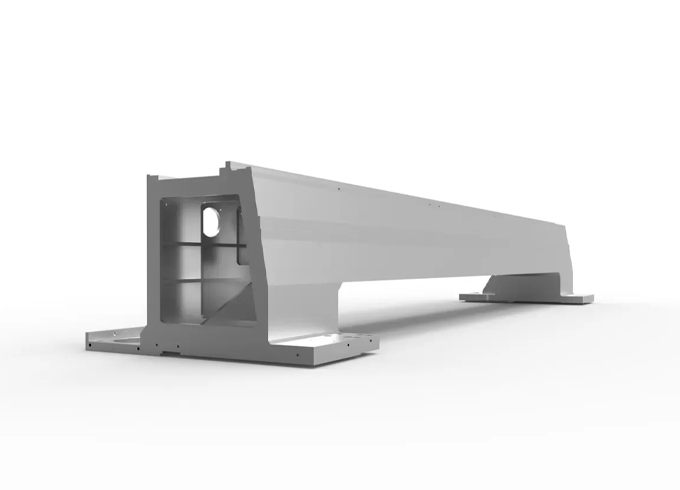

Cast Aluminum Fiber Laser Cutting Machine Beam

We enhanced the cast iron crossbeam by using a cast aluminum one to boost the fiber laser cutting's acceleration. The crossbeam is lighter while maintaining stiffness.

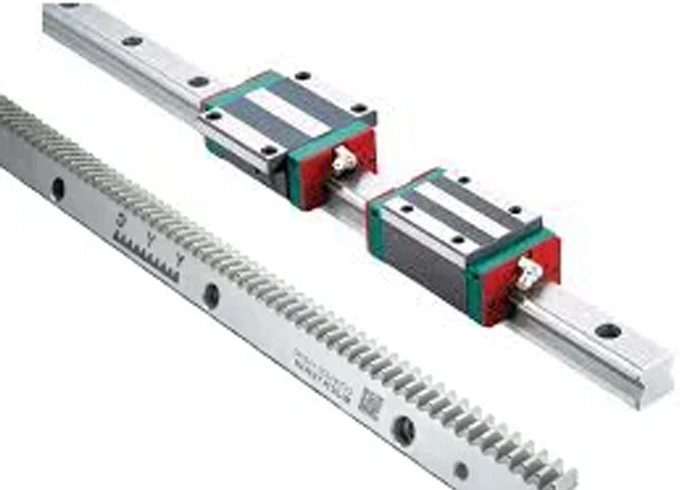

Automatic Lubrication

The process is quick and easy thanks to the timed automatic lubrication system, which starts and dispenses lubricating oil according to the machine's operating schedule.

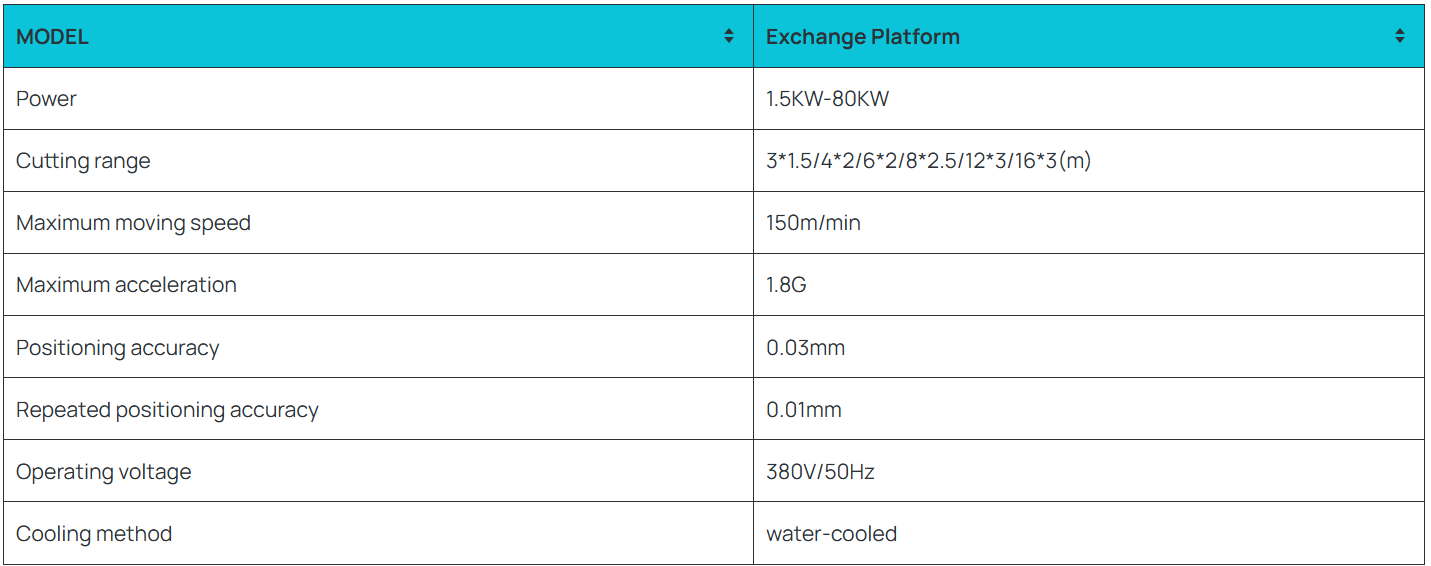

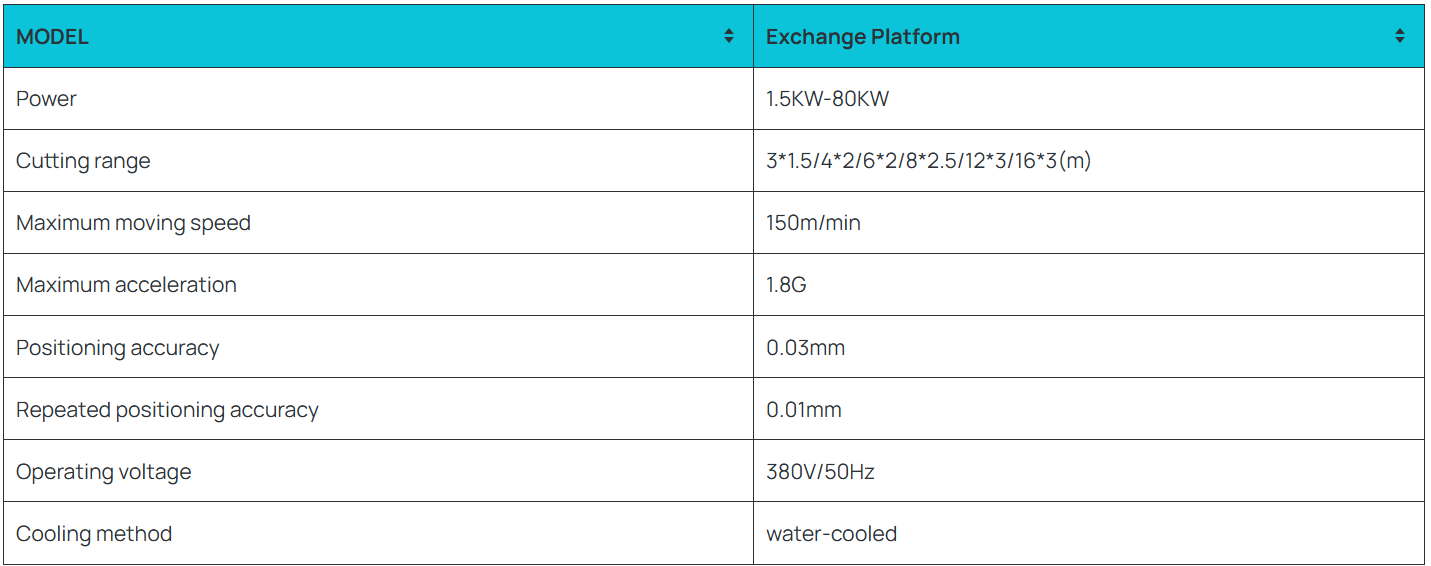

Technical Specifications of 3D Cutting Robotic Arm

If you require further detailed parameters, please do not hesitate to contact us.

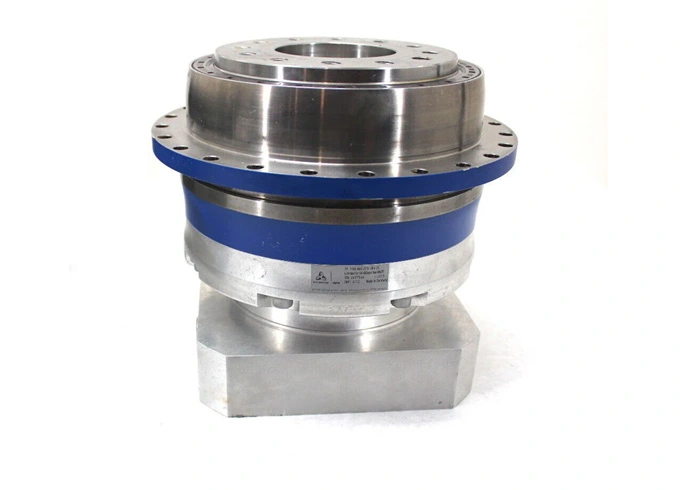

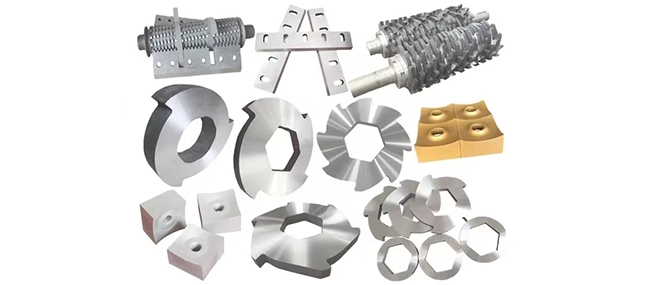

Processing Equipment of 3D Cutting Robotic Arm

We focus on every aspect of the machine and are dedicated to making the best machine tools possible for our clients.

English

English