Performance Characteristics of CNC Laser Tube Cutting Machine

Multi-functional Processing Capability: In addition to conventional round, square, and rectangular tubes, this equipment can also process complex-shaped profiles, such as I-beams, L-shaped steels, and other structural steels. This versatile processing capability allows the equipment to excel in various industrial applications and meet different types of cutting needs. Whether in construction, manufacturing, or other industries, this equipment can provide efficient and precise cutting solutions.

Fully Automatic Loading and Unloading: The equipment is equipped with a fully automatic loading and unloading system. Once the raw material tubes are placed in the loading mechanism, the machine can automatically complete the processes of loading, cutting, and unloading. This fully automated design not only significantly reduces manual operation time and labor intensity but also improves production efficiency and safety. The fully automatic loading and unloading system ensures the continuity and efficiency of the cutting process, making the production flow smoother.

High-Precision Cutting: Based on the bus real-time system and integrated control technology, the equipment can achieve high-precision perforation and cutting. The cutting speed at tube corners is fast, corner following is stable, and the cutting quality is reliable. This high-precision cutting capability not only enhances product quality but also reduces material waste, thereby lowering production costs. The high-precision cutting technology allows the equipment to maintain excellent performance even when handling complex shapes and high-demand cutting tasks.

Dynamic Real-Time Cutting Simulation: The equipment is equipped with dynamic real-time cutting simulation, allowing operators to view the cutting process. This real-time simulation feature not only enhances operation visibility but also enables operators to identify and solve potential problems promptly, thereby improving production efficiency and product quality. The real-time cutting simulation makes the operation more intuitive and convenient, further enhancing the user experience of the equipment.

Standard Configuration of CNC Laser Tube Cutting Machine

Operating System: The equipment is equipped with a powerful operating system that features real-time compensation for tube center deviation, effectively reducing the requirements for tube clamping. The operating system also supports simple 3D graphic drawing, capable of handling complex tool path editing for angle steel, channel steel, I-beams, etc. The common edge cutting function further improves cutting efficiency, saving time and materials. The powerful operating system ensures that the equipment remains efficient and precise even when handling complex cutting tasks.

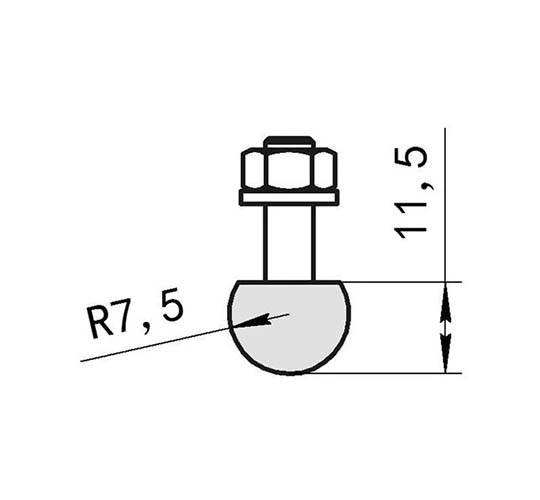

High-Performance Cutting Head: The high-performance cutting head is one of the core components of the equipment, capable of achieving nearly perfect cutting results. Whether it's circular, square, rectangular tubes, or various H-shaped, I-shaped, L-shaped steel profiles, this cutting head can handle them with ease. Its high precision and high efficiency in cutting enable it to perform excellently in various industrial applications. The high-performance cutting head not only provides clean, smooth cutting edges but also significantly reduces material waste, improving production efficiency.

Intelligent Unloading Support Unit: The intelligent unloading support unit plays a crucial role during the cutting process. The support plate intelligently rises and falls according to the changes in the profile cross-section shape and automatically moves to the appropriate position based on the length of the workpiece. For long workpieces, three chucks hold and cut simultaneously, ensuring cutting accuracy. This intelligent design not only enhances cutting precision but also reduces the need for manual intervention, thereby increasing production efficiency. The application of the intelligent unloading support unit makes the cutting process more efficient, precise, and reliable.

Automatic Loading System: The automatic loading system is an indispensable part of the equipment, making the loading work easier and faster. Equipped with an automated tube loading system, it can significantly reduce the time and labor intensity of manual operations, improving production efficiency. The automatic loading system can automatically transport tubes to the cutting position according to production needs, ensuring the continuity and efficiency of the cutting process. Its intelligent design makes the loading process smoother, reducing errors and delays caused by manual operations. The automatic loading system not only enhances production efficiency but also improves the safety and reliability of the production process.

Conclusion of CNC Laser Tube Cutting Machine

Cutting equipment, with its multi-functional processing capability, fully automatic loading and unloading, high-precision cutting, and dynamic real-time cutting simulation features, significantly improves production efficiency and product quality. Its powerful standard configuration, including the operating system, high-performance cutting head, intelligent unloading support unit, and automatic loading system, allows the equipment to excel in various industrial applications. Through continuous technological innovation and optimization, these devices will continue to drive the industry towards higher efficiency and intelligence, providing enterprises with efficient, precise, and reliable cutting solutions.

English

English